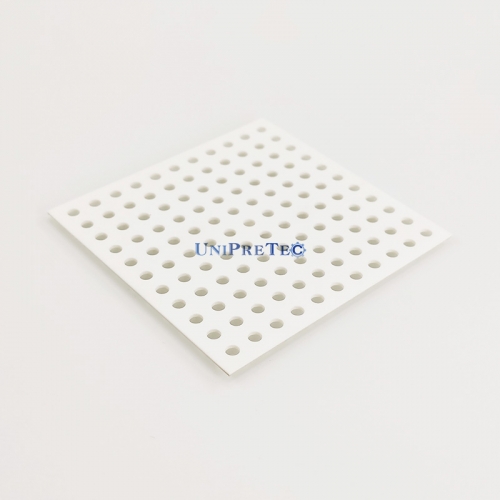

▼ Description of Ceramic Substrates

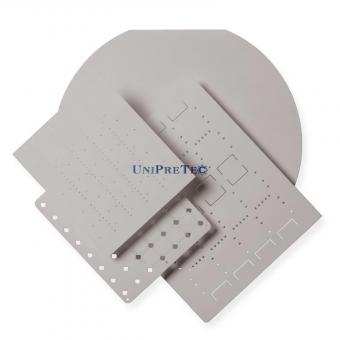

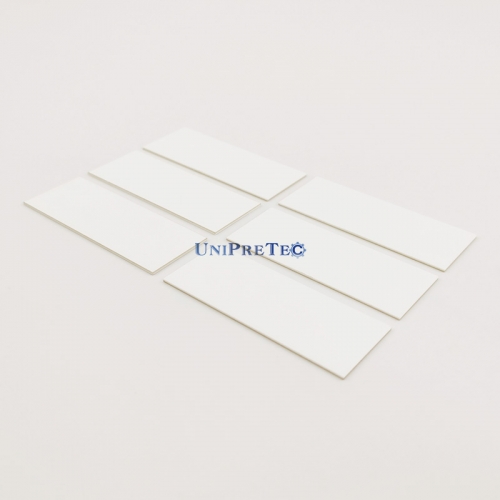

Currently, there are four main types of substrate materials commonly used in electronic packaging: polymer substrate; metal substrate; composite substrate; ceramic substrates. The ceramic substrate material is widely used in electronic packaging substrate for its following advantages (see below table). UNIPRETEC is good at providing alumina ceramic substrates made of two main grades: 96% Alumina Ceramic and 99% Alumina Ceramic. The ceramic substrates can be etched various graphics like the PCB, with great current carrying capacity. It is suitable for products with high heat generation (high-brightness LED, solar energy), and its excellent weather resistance is more suitable for harsh outdoor environments.

High Mechanical Strength High Mechanical Strength

|

Good Thermal Conductivity Good Thermal Conductivity

|

Excellent Electrical Insulation Excellent Electrical Insulation

|

Outstanding Chemical Stability Outstanding Chemical Stability

|

Extremely High Service Temperature Extremely High Service Temperature

|

Small Thermal Expansion Coefficient Small Thermal Expansion Coefficient

|

▼ Properties of Alumina Substrates/Sheets/Plates

ITEM

|

UNIT

|

A960

|

Main Content

|

-

|

Al2O3 > 96%

|

Density

|

g/cm3

|

> 3.7

|

Color

|

-

|

White

|

Water Absorption

|

%

|

0

|

Warpage

|

-

|

< 2‰

|

Standard Surface Roughness (Ra)

|

um

|

0.2 - 0.7

|

Flexural Strength

|

Mpa

|

380

|

Thermal Conductivity (25 °C)

|

W/m.K

|

> 25

|

Thermal Expansion Coefficient (25 - 300 °C)

|

10-6 mm/°C

|

6.5 - 7.5

|

Thermal Expansion Coefficient (300 - 800 °C)

|

10-6 mm/°C

|

6.5 - 8.0

|

Max. Working Temperature

|

°C

|

1,200

|

Dielectric Strength

|

KV/mm

|

> 17

|

Dielectric Constant

|

1 MHz

|

9 - 10

|

Electrical Resistivity (25 °C)

|

Ω·cm

|

> 1014

|

∆ The data is offered for reference only, exact data will vary depending on producing method & part configuration.

▼ Standard Dimensions and Tolerance

Length and Width

|

Thickness

|

Tolerance (Thickness)

|

110mm x 110mm (4.3" x 4.3")

|

0.25mm (0.010")

|

±0.03mm(<1.0mm)

|

114mm x 114mm (4.5" x 4.5")

|

0.38mm (0.015")

|

±0.05mm(1.0mm - 1.5mm)

|

120mm x 120mm (4.7" x 4.7")

|

0.50mm (0.020")

|

±0.07mm(>1.5mm)

|

127mm x 127mm (5.0" x 5.0")

|

0.63mm (0.250")

|

±0.10mm(>2.0mm)

|

130mm x 140mm (5.1" x 5.5")

|

0.76mm (0.030")

|

|

109mm x 130mm (4.3" x 5.1")

|

1.00mm (0.390")

|

Tolerance (Length and Width)

|

190mm x 140mm (7.5" x 5.5")

|

2.00mm (0.790")

|

+0.25mm/-0.05mm

|

▼ Surface Roughness of Ceramic Substrates

All substrates are grinded with surface roughness Ra 0.3-0.6um. We can also do surface polishing, one-side polishing or double-side polishing with surface roughness Ra 0.05-0.10um.

▼ Applications of Alumina Sheets/Substrates/Plates

● LED Packages

|

● Power Modules

|

● Wafer Bonding

|

● Heat Dissipation Substrate

|

● Substrate for Chip Resistors

|

● HIC Substrate/Plate for Heat Dissipation

|

● FAX Substrates for Thermal Printer Head

|

● ...More

|

High Mechanical Strength

High Mechanical Strength Good Thermal Conductivity

Good Thermal Conductivity Excellent Electrical Insulation

Excellent Electrical Insulation Outstanding Chemical Stability

Outstanding Chemical Stability Extremely High Service Temperature

Extremely High Service Temperature Small Thermal Expansion Coefficient

Small Thermal Expansion Coefficient