▼ Material Description

When it comes to providing good thermal conductivity and high electrical insulation features, aluminum nitride substrate is a superb option because of its efficacy. Aluminum nitride sheets are widely used in the semiconductor application industry instead of beryllium oxide (BeO) since aluminium nitride is non-toxic and does not produce dangerous vapors when grinded and machined. Aluminum nitride ceramic substrate has a thermal expansion and isolation coefficient which closely matches the silicon wafer product, making it useful in applications in electronics that often have high temperatures and heat dissipation problems.

▼ Features and Properties

√ Small Dielectric Constant

|

√ Good Mechanical Strength

|

√ High Thermal Conductivity

|

√ Good Smoothness / Flatness

|

√ Excellent in Electrical Insulation

|

√ Excellent in Thermal Shock Resistance

|

√ Thermal Expansion Coefficient Similar to Silicon

|

√ Excellent Resistance against Oil, Acid and Alkali

|

ITEM

|

UNIT

|

ALN

|

Main Content

|

-

|

AlN > 95%

|

Density

|

g/cm3

|

> 3.3

|

Color

|

-

|

Grey

|

Water Absorption

|

%

|

0

|

Warpage

|

-

|

< 2‰

|

Standard Surface Roughness (Ra)

|

um

|

0.3 - 0.6

|

Flexural Strength

|

Mpa

|

440

|

Thermal Conductivity (25 °C)

|

W/m.K

|

> 175

|

Thermal Expansion Coefficient (25 - 300 °C)

|

10-6 mm/°C

|

2 - 3

|

Thermal Expansion Coefficient (300 - 800 °C)

|

10-6 mm/°C

|

2.5 - 3.5

|

Max. Working Temperature

|

°C / °F

|

1,200 / 2,190

|

Dielectric Strength

|

KV/mm

|

> 17

|

Dielectric Constant

|

1 MHz

|

17

|

Electrical Resistivity (25 °C)

|

Ω·cm

|

> 1014

|

∆ The data is offered for reference only, exact data will vary depending on producing method and part configuration.

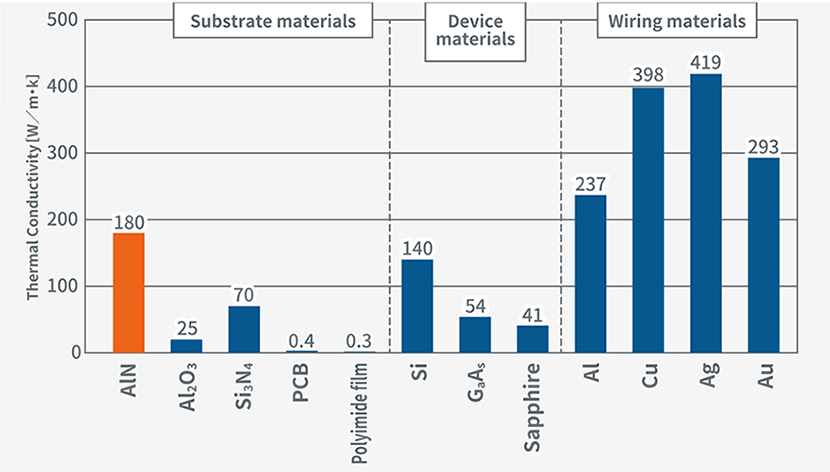

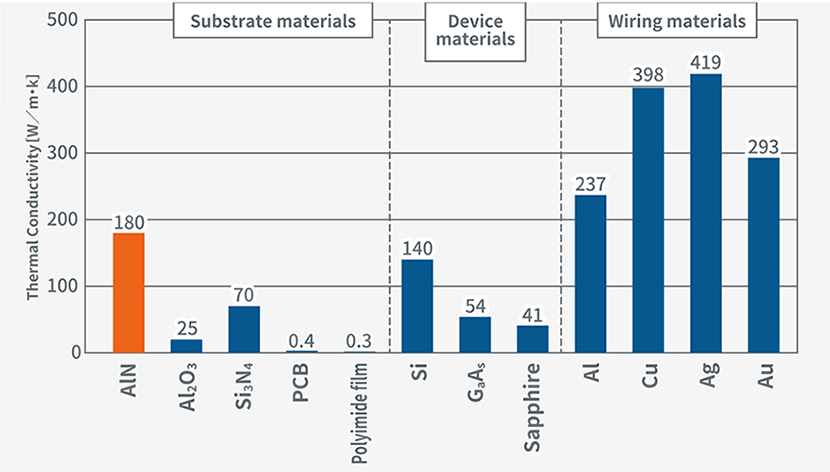

▼ Properties Comparison : Thermal Conductivity

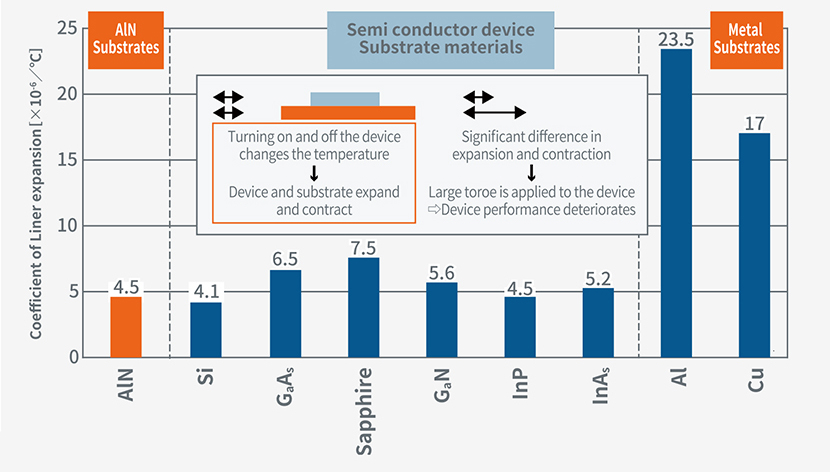

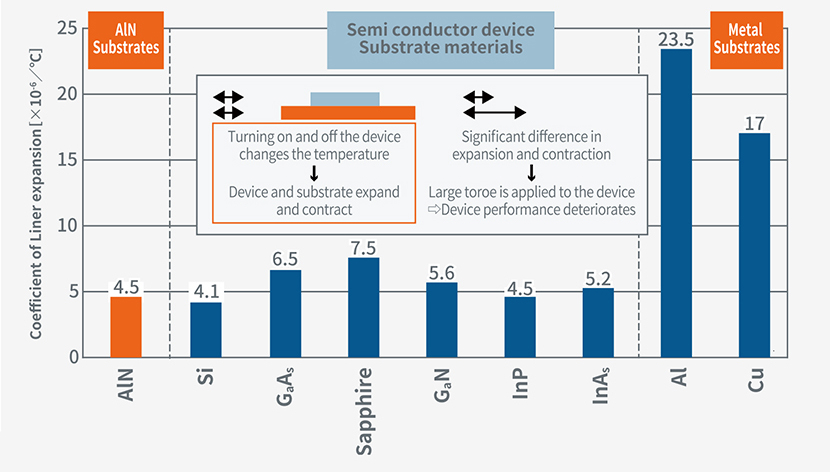

▼ Properties Comparison : Coeffecient of Thermal Expansion

▼ Standard Dimensions and Tolerance

Length and Width

|

Thickness

|

Tolerance (Thickness)

|

110mm x 110mm (4.3" x 4.3")

|

0.25mm (0.010")

|

±0.03mm(<1.0mm)

|

114mm x 114mm (4.5" x 4.5")

|

0.38mm (0.015")

|

±0.05mm(1.0mm - 1.5mm)

|

120mm x 120mm (4.7" x 4.7")

|

0.50mm (0.020")

|

±0.07mm(>1.5mm)

|

127mm x 127mm (5.0" x 5.0")

|

0.63mm (0.250")

|

±0.10mm(>2.0mm)

|

130mm x 140mm (5.1" x 5.5")

|

0.76mm (0.030")

|

|

109mm x 130mm (4.3" x 5.1")

|

1.00mm (0.390")

|

Tolerance (Length and Width)

|

190mm x 140mm (7.5" x 5.5")

|

2.00mm (0.790")

|

+0.25mm/-0.05mm

|

▼ Surface Roughness of AlN Substrates

All substrates are grinded with surface roughness Ra0.3-0.6. We can also do surface polishing, one-side polishing or double-side polishing with surface roughness Ra0.02-0.05.

▼ Applications of Aln Ceramic Substrates

● LED Packages

|

● Power Modules

|

● Wafer Bonding

|

● Heat Dissipation Substrate

|

● Substrate for Chip Resistors

|

● HIC Substrate/Plate for Heat Dissipation

|

● FAX Substrates for Thermal Printer Head

|

● ...More

|