Material Yttria Stabilized Zirconia(Y2O3-ZrO2) is used to make the Valve Balls & Seats for sucker rod pumps.

- Ceramic valve balls have extremely high chemical stability and hardness, second only to diamond, wear resistance, corrosion resistance, and high temperature resistance.

- The ball is manufactured with advanced grinding equipment and technology, with high round precision and good surface quality. After being grind with the valve seat, it can achieve good sealing performance. The static pressure test showed no leakage after 10000 times opening-closing.

- It has completely changed the shortcomings of the metal hard-seal ball valve that it is easy to leak, the torque is large, and the sealing surface is not corrosion resistant.

- Used in the high-speed back and forth movement of sucker rod pump to stop leakage. The good abrasion resistance of ceramic makes it durable, extremely reliable, and has a long service life. It can well replace traditional steel balls, glass balls, etc. It is durable, reduces maintenance procedures, improves the quality of the pump, and is economical. It is also suitable for check valves, sprayers and various equipment.

- Used in high-hardness granular medium, or soft granular but corrosive medium, ceramic valve ball and valve seat has unparalleled advantages.

Advantages of Zirconia Ceramic Valve Balls and Seats for Sucker Rod Pump

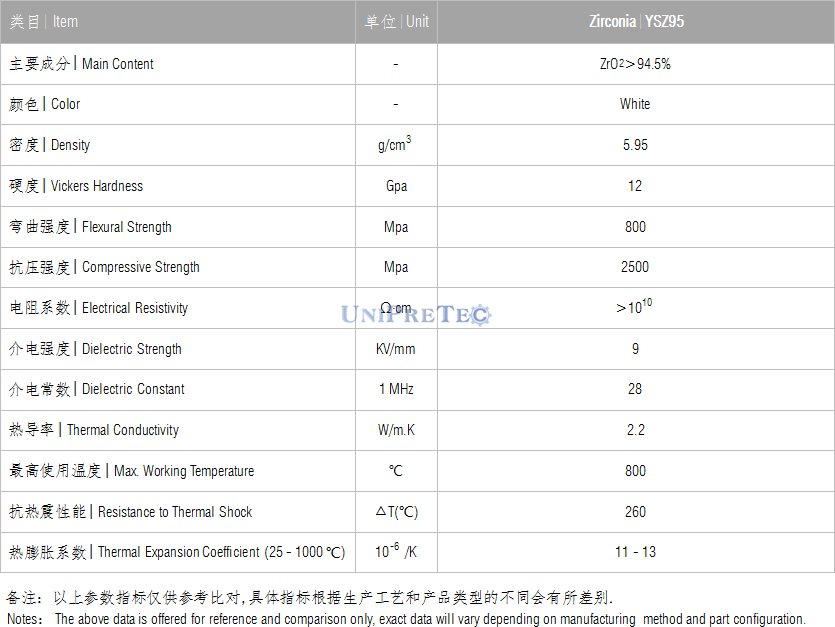

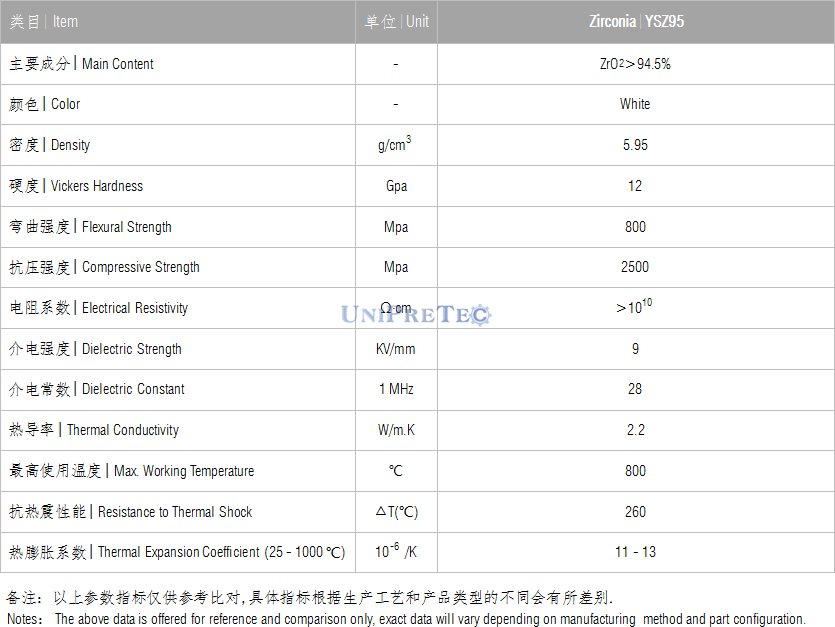

Materials Data Sheet of ZrO2 Zirconia Ceramic Valve Balls and Seats for Sucker Rod Pump

Manufacturing Processes of ZrO2 Zirconia Ceramic Valve Balls and Seats for Sucker Rod Pump