FAQ's

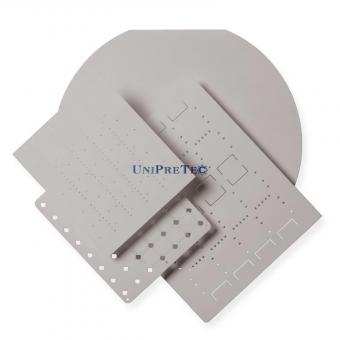

Frequently Asked Questions... Q1: What are advanced ceramics? >>> Advanced ceramics - also referred to as engineering, structural or technical ceramics - have been processed to be very pure and, in general, have superior properties to unrefined ceramics. Many are man-made, i.e. they do not occur naturally, e.g. silicon nitride, and their properties can be enhanced to produce very high strength at high temperatures, good corrosion resistance, etc. Q2: What types of ceramic do you supply? >>> Alumina(Al2O3) in purity from 90% to 99.7%, Aluminium Nitride(AlN), Cordierite, Hot Pressed Boron Nitride(BN), Machinable Glass Ceramic(Macor), Mullite, Silicon Nitride(Si3N4) and Zirconia(ZrO2). Q3: Can I machine the ceramics myself? >>> The harder ceramics like alumna and zirconia will require diamond tooling but other materials like Machinable Glass Ceramic and Hot Pressed Boron Nitride can be machined. To get the right result it does take time, experience and semi-specialised tooling but it can be done and many of our customers take advantage of this when they need extremely fast solutions in-house. Q4: Do you ship internationally? >>> Yes, we can ship to virtually anywhere in the world. Typically we will use international express, like DHL, EMS, Fedex, UPS, TNT... We can also arrange shipments on your own courier account if you prefer to take this route. Q5: Can I get a sample or purchase a small quantity? >>> Yes, we are happy to supply small samples of material for you to test. We can also supply prototype quantities through to volume production to suit your needs. Q6: How long will it take for you to send me a quote? >>> This depends totally on the complexity of your requirements. For simple items such as bars and rods, we can generally supply a quotation within 24 hours. Q7: What's the delivery time? >>> For our standard products, like ceramic protection tubes and insulating rods, delivery time is normally 7 working days. For hot pressed boron nitride and machinable glass ceramic, it's about 10 working days. For customized products made of alumina, zirconia, boron carbide and silicon nitride, total producing time is about 20-30 working days. For more complex items, we should be able to respond within 1 to 3 days. If you have any other specific question on any of our products or services, please contact us by email info@unipretec.com or by telephone +86 592 5510319.

View More

Merry Christmas and Happy New Year 2021 to you and your families!

Dec 23 , 2020

Merry Christmas and Happy New Year 2021 to you and your families!

Dec 23 , 2020

New Furnaces for Manufacturing Hot Pressed Boron Nitride

Oct 23 , 2019

New Furnaces for Manufacturing Hot Pressed Boron Nitride

Oct 23 , 2019

New Boron Nitride for Horizontal Continuous Steel Casting

2017-10-13

New Boron Nitride for Horizontal Continuous Steel Casting

2017-10-13

NEW Investment of Automatic Dry Pressing Equipments

2018-03-04

NEW Investment of Automatic Dry Pressing Equipments

2018-03-04