With the development of technology and electronics, ceramic substrates are more and more widely used. Compared with aluminum substrates, part of the original market is gradually replaced by ceramic substrates. So what are the outstanding advantages of ceramic substrates compared with aluminum substrates?

1. What is a ceramic substrate and what is an aluminum substrate

What is a ceramic substrate

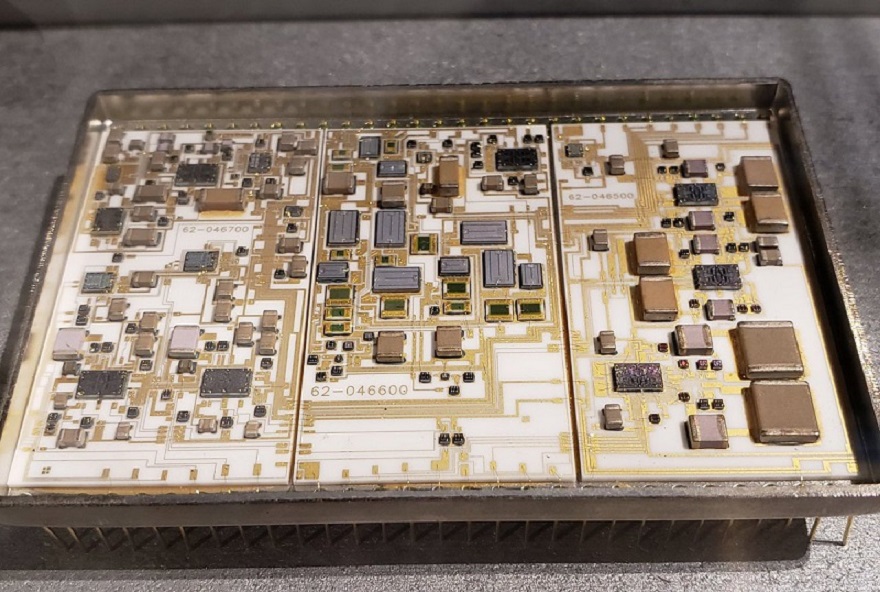

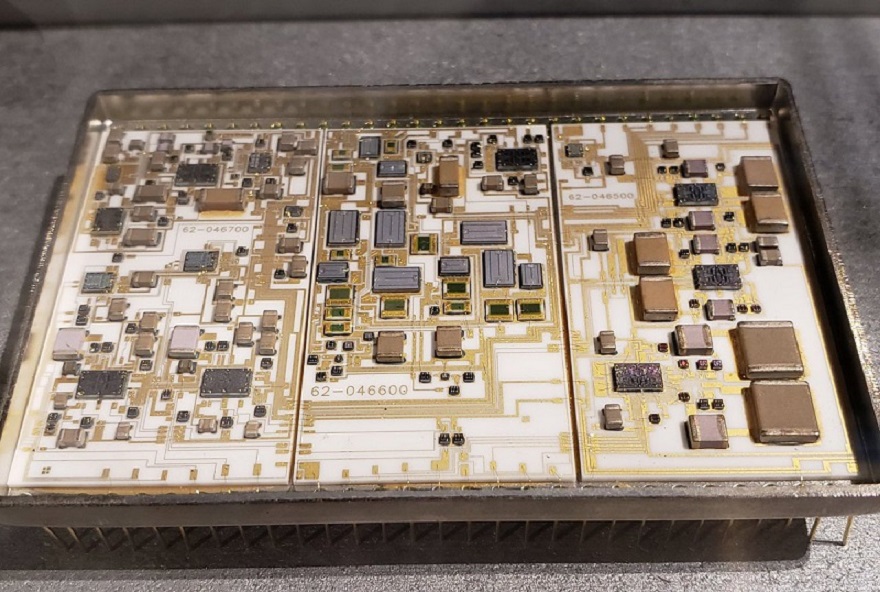

Ceramic substrate refers to a special process board in which copper foil is directly bonded to alumina (Al2O3) or aluminum nitride (AlN) ceramic substrate surface (single-sided or double-sided) at high temperature. The ultra-thin composite substrate has excellent electrical insulation properties, high thermal conductivity, excellent solderability and high adhesion strength, and can be etched into various patterns like a PCB board, and has a large current carrying capacity. Therefore, ceramic substrates have become the basic materials for high-power power electronic circuit structure technology and interconnection technology.

What is an aluminum substrate

Aluminum substrate is a metal-based copper clad laminate with good heat dissipation function. Generally, a single-sided panel consists of three-layer structure, which are circuit layer (copper foil), insulating layer and metal base layer. For high-end use, there are also double-sided designs with a structure of circuit layer, insulating layer, aluminum base, insulating layer, and circuit layer. Very few applications are multi-layer boards, which can be made by laminating ordinary multi-layer boards with insulating layers and aluminum bases.

2. Comparison of composition and working principle of ceramic substrate and aluminum substrate

The ceramic substrate has the characteristics of insulation, so the ceramic substrate is composed of a circuit layer and a metal base layer, and the insulating layer is omitted. Its working principle is that the surface of the power device is mounted on the circuit board layer, and the heat generated by the device is directly transferred by the metal base layer, so as to dissipate the heat of the device.

The aluminum substrate is composed of a circuit layer, an insulating layer and a metal base layer. The surface of the device is mounted on the circuit layer, and the heat generated during the operation of the device is transferred from the insulating layer to the metal base layer, and then the metal base layer transfers the heat out, thereby realizing the heat dissipation of the device.

3. Property comparison of ceramic substrate and aluminum substrate

|

Item

|

Ceramic Substrate

|

Aluminum Substrate

|

|

Material

|

Alumina, Aluminum Nitride

|

Aluminum, Copper, Iron

|

|

Surface Finishing

|

OSP, ENIG, GP, immersion silver,

immersion Tin, NiPdAu, platinum

|

HASL, immersion Tin,

immersion silver

|

|

Layer Qty.

|

single-sided, double-sided,

multi-sided

|

single-sided, double-sided

|

|

Copper Layer

Thickness

|

1-500um

|

35-240um

|

|

Min. Line Distance

|

0.1um

|

0.1um

|

|

Deformation

|

no deformation

|

≤0.5%

|

|

Processing Technic

|

DBC/DPC/AMB/HTCC/LTCC

|

HTCC/LTCC/DBC

|

|

Bonding

|

not easy peeled off

|

easy peeled off

|

|

Plate Thickness

|

0.25mm, 0.38mm, 0.5mm,

0.635mm, 1.0mm, 2.0mm

|

0.3-5.0mm

|

|

Size

|

customized

|

5*5mm-1185*480mm

|

4. Performance comparison of ceramic substrate and aluminum substrate

Item

|

Ceramic Substrate

|

Aluminum Substrate

|

|

Mechanical Performance

|

good size precision,

can do multi-layer plating

|

good mechanical durability

|

|

Electrical Property

|

excellent insulating property

low dielectric constant

low dielectric loss

|

In an environment with high temperature

and high humidity, chemical and physical

changes are prone to occur, performance

is not stable

|

|

Thermal Property

|

high temperature resistant

corrosion resistant

high thermal conductivity

|

good thermal conductivity, but thermal

property is largely affected after insulating

layer added during packaging

|

|

Other Properties

|

good chemical stability

easy to get metalized with complicated

path and good bonding

chemical corrosion resistant

low radiation rate

no moisture

no pollution

|

rich in raw material

mature techinical process

cheap price

|

5. Advantages of ceramic substrate and aluminum substrate

|

Ceramic Substrate

|

Aluminum Substrate

|

coefficient of thermal expansion close to that of silicon

|

meet requirement of ROHS

|

|

reduce solder layers, reduce thermal resistance,

reduce space, and improve production yield

|

reduce product operating temperature,

improve product power density and reliability,

and extend product life

|

|

under the same current carrying, the copper

foil line width of 0.3mm thick is only 10% of

that of ordinary printed circuit boards

|

reduce product size

reduce hardware and assembly costs

|

|

excellent thermal conductivity makes the package

of the chip very compact, which greatly increases

the power density and improves the reliability of

the system and device

|

Not easy to break, good mechanical durability

|

|

high insulation withstand voltage, ensuring life safety

and equipment protection ability

|

|

|

enables new packaging and assembly methods for

highly integrated and compact products

|

|

6. Applications of ceramic substrate and aluminum substrate

Ceramic Substrate

|

Aluminum Substrate

|

|

high-power power semiconductor modules;

semiconductor refrigeration amplifiers,

audio amplifiers, preamplifiers, power appliances,

electronic heaters; power control circuits,

power hybrid circuits.

|

Audio equipment: input, output amplifiers,

balanced amplifiers, audio amplifiers, preamplifiers

|

|

Intelligent power components;

high frequency switching power supplies,

solid state relays

|

power supply equipment: switching regulator,

DC/AC to relay converter, SW adjustment period, etc.

|

|

automotive electronics

aerospace and military electronics

|

communication electronic equipment: high frequency

booster, filter, transmission circuit

|

|

solar panel components;

telecommunications professional exchange

receiver, receiving system;

industrial electronics such as laser

|

automotive: Electronic regulators, ignitions,

power controllers

|

medical equipment, sensor field

|

computer: CPU floppy disk drive, power supply unit

|

|

power modules: rectifiers, solid state relays,

rectifier bridges, etc.

|