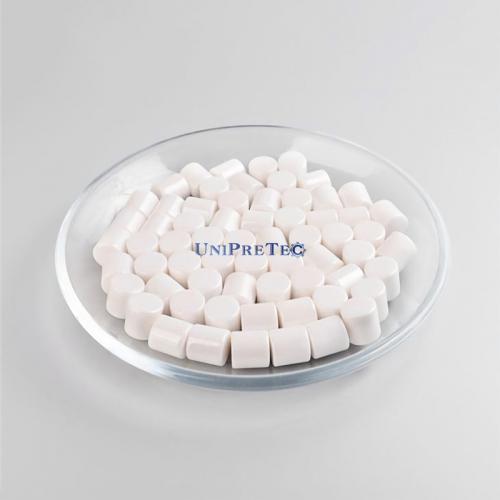

▼ Description of Ceramic Grinding Media

Ceramic Grinding Media is one of the best choice of grinding media materials, it has pearl-like luster and smooth working spherical surface. Compared with traditional grinding media, grinding media made of technical ceramics has the characteristics of high density, high hardness, high toughness, etc., so that it has grinding efficiency and service life unmatched by traditional grinding media. Furthermore, the chemical properties of technical ceramics are stable and can prevent pollution of materials, increase production and reduce production costs. The following is a summary of the features of ceramic grinding beads and balls.

√ Wear Resistant

|

√ High Hardness

|

√ Smooth Surface

|

√ Good Roundness

|

√ Very Long Service Life

|

√ High Grinding Efficiency

|

√ High Chemical Resistance

|

√ High Density (max. 6.2 g/cm3)

|

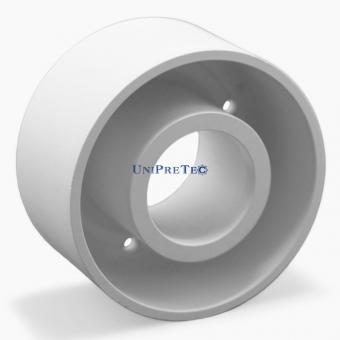

▼ The Types of Ceramic Grinding Media

|

Yttria Stabilized Zirconia Beads

|

Ceria Stabilized Zirconia Beads

|

Zirconium Silicate Grinding Beads

|

UNIPRETEC provides ceramic grinding media made of the three main types technical ceramics: Yttria Stabilized Zirconium Oxide (YSZ95), Cerium Stabilized Zirconium Oxide (CSZ80), and Zirconium Silicate Ceramic (ZS65). Most of our product inventory is sufficient and the market covers the whole world. Following is the material characteristics sheet for your reference.

ITEM

|

UNIT

|

YSZ95

|

CSZ80

|

ZS65

|

Main Content

|

-

|

94.5% ZrO2

5% Y2O3

|

80% ZrO2

20% CeO2+Others

|

65% ZrO2

>30% SiO2

|

True Density

|

g/cm3

|

6.00

|

6.10

|

4.00

|

Apparent Density

|

g/cm3

|

> 3.70

|

> 3.75

|

> 2.50

|

Crush Strength (diameter 2.0mm)

|

KN

|

2.8

|

2.2

|

1.5

|

Hardness (HV10)

|

-

|

1,200

|

1,150

|

860

|

Color

|

-

|

White

|

Yellow

|

White

|

|

Specification

|

mm

|

Φ0.5-50

|

Φ0.5-50

|

Φ0.5-50

|

|

Package

|

Kilograms/Drum

|

25

|

25

|

25

|

∆ The data is offered for reference only, exact data will vary depending on producing method & part configuration.

▼ The Standard Sizes in Stock (diameter in millimeter)

0.1-0.2

|

1.0-1.2

|

2.2-2.4

|

3.4-3.6

|

5.8-6.3

|

20.0

|

0.2-0.3

|

1.2-1.4

|

2.4-2.6

|

3.6-3.8

|

6.3-6.8

|

25.0

|

0.3-0.4

|

1.4-1.6

|

2.6-2.8

|

4.0-4.3

|

8.0

|

30.0

|

0.4-0.6

|

1.6-1.8

|

2.8-3.0

|

4.3-4.8

|

10.0

|

40.0

|

0.6-0.8

|

1.8-2.0

|

3.0-3.2

|

4.8-5.3

|

12.0

|

50.0

|

0.8-1.0

|

2.0-2.2

|

3.2-3.4

|

5.3-5.8

|

15.0

|

...

|

▼ The Applications of Ceramic Grinding Media

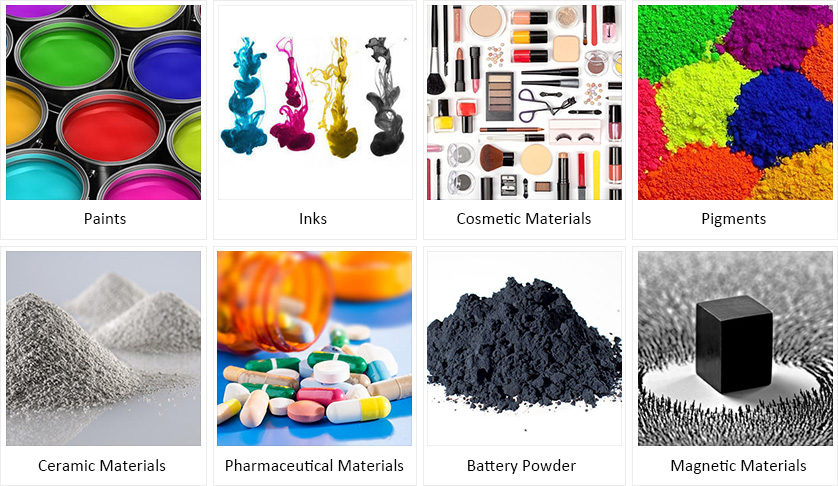

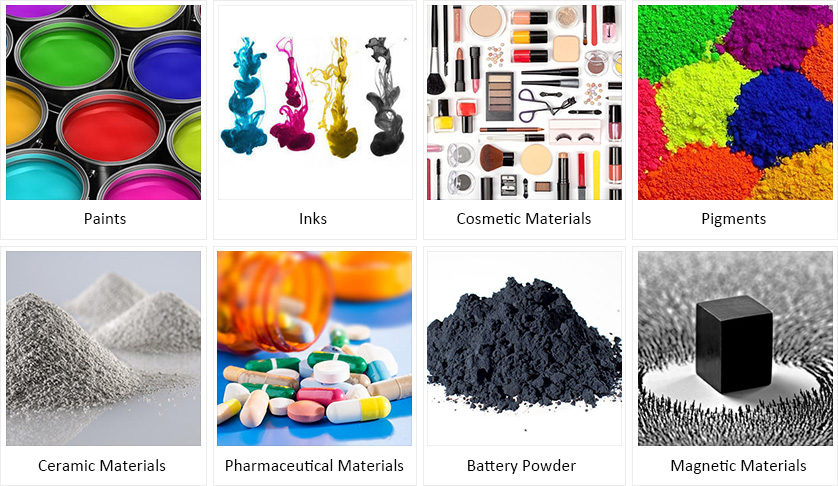

Ceramic grinding balls and beads can be used in a variety of sand mills, stripping machines, stirring ball mills, roller ball mills, and other applications. Many materials, such as electronic slurry, ceramic powder, magnetic materials, battery raw materials, rare earth materials, non-metallic minerals, paints, pigments, inks, heavy calcium, titanium dioxide, pesticides, food and pharmaceutical raw materials, and so on, are suitable for processing with ceramic balls and beads. They can provide efficient, clean, and cost-effective dispersion and grinding.