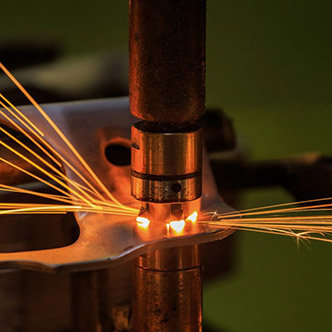

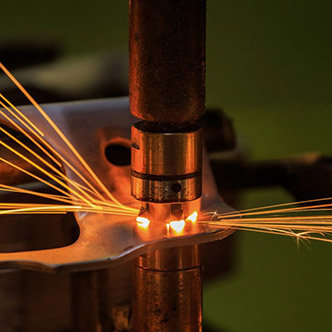

Welding Application

For the welding process, UNIPRETEC supplies advanced ceramics as the ideal materials for welding tools such as welding rollers, welding centering pins or gas nozzles. Parts made of advanced ceramics are with particular hardness and wear resistance, very high temperature resistance and chemical resistance. They enable a multiplied service life, shorten the overall set-up times, extend the machine running times and improve the quality of the end product. In other words, advanced ceramics in the welding process create added value. ▼ Silicon Nitride Weld Rollers for HP ERW Electric resistance welding (ERW) encompasses a range of joining techniques where faying surfaces are heated to the point of fusion via electrical resistance. This high-temperature process is mechanically intensive, requiring extremely strong and wear resistant materials that can withstand severe thermal shock. Although stainless steel welding rollers will provide significant improvements in terms of precision, they will fail due to thermal and mechanical breakdown far quicker than silicon nitride. The electrical conductivity of stainless steel welding rollers can also be problematic, contributing to material pick-up problems that are commonplace in non-ferrous metal joining. Silicon nitride welding rollers vastly outperform steel alternatives, with significantly improved thermal shock resistance and strength, notwithstanding the material’s non-conductivity. Silicon nitride ceramic material from UNIPRETEC features a compressive strength of up to 3,500 MPa and a thermal shock resistance of Δ900°C. This exceeds the requirements for seam welding, providing a number of advantages over conventional welding rollers, including better product quality, fewer weld failures, reduced roller maintenance requirements, and reduced cooling times. Subsequently, silicon nitride welding rollers can reduce HF-ERW power by up to 30% and can outperform steel components by a factor of up to 10x.