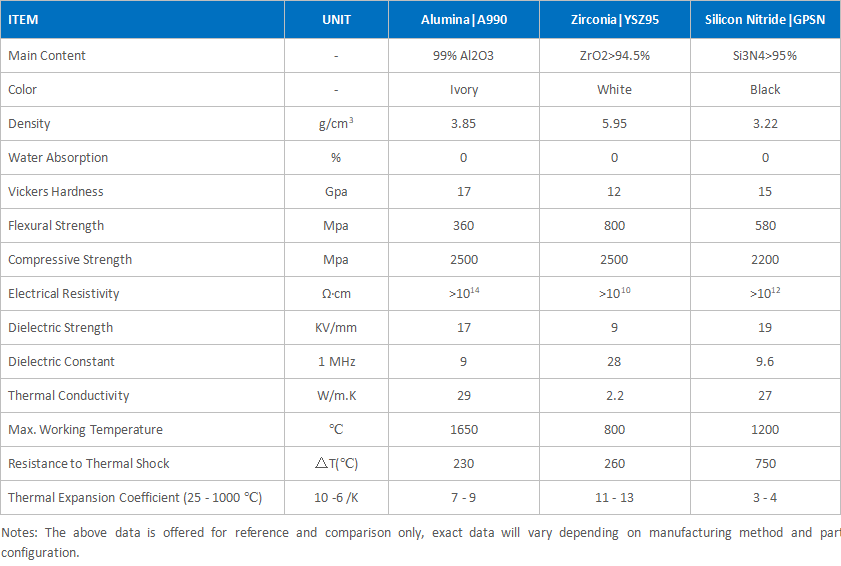

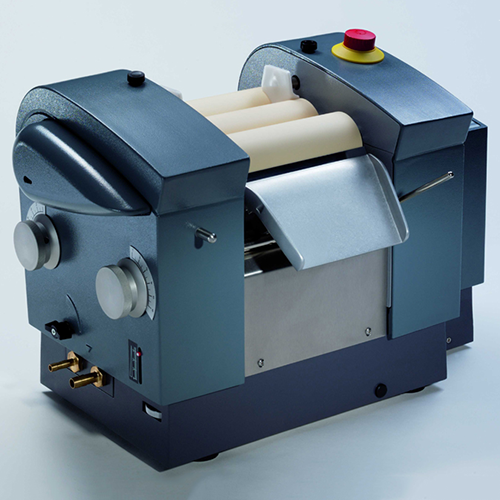

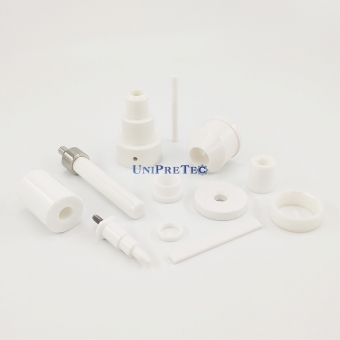

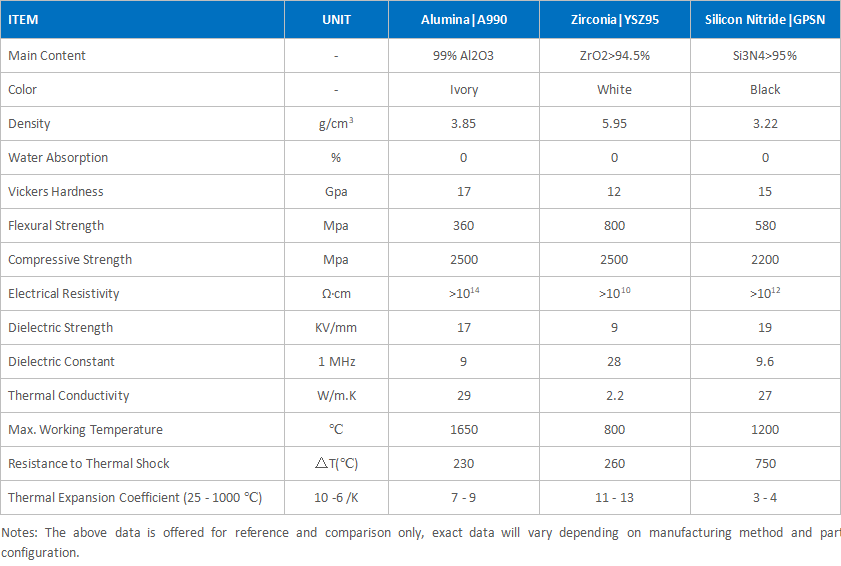

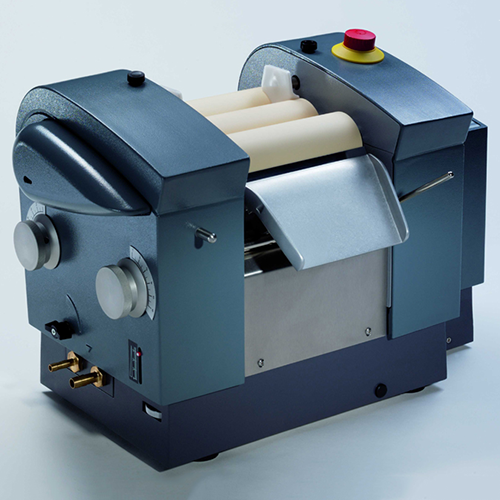

UNIPRETEC provides ceramic rollers for laboratory three-roll grinders. The laboratory three-roll ceramic grinder is suitable for paste or high-viscosity materials that need to be dispersed and require high fineness, such as ink, color paste, adhesive, biological, food, cosmetics, coatings, photovoltaic materials and other industries product materials dispersion grinding. By squeezing the surfaces of three horizontal rollers, the distance between the rollers is manually adjusted, and the grinding effect is achieved by friction at different speeds. Equipped with an emergency brake button to prevent equipment damage caused by falling foreign objects. UNIPRETEC's rollers are made of technical advanced ceramic materials, including high-purity alumina(Al2O3), zirconia(ZrO2) and silicon nitride(Si3N4). Ceramic material has high hardness, second only to diamond, and is an inorganic material, so it has very good wear resistance and corrosion resistance, so it has a very long service life and no pollution.

Features of Al2O3 Si3N4 ZrO2 Ceramic Rollers for Laboratory Triple Three Roll Mill:

High hardness High hardness

|

No pollution No pollution

|

Great chemical inertness Great chemical inertness

|

Long serice life Long serice life

|

Wear & Corrosion resistant Wear & Corrosion resistant

|

High using temperature High using temperature

|

Applications of Al2O3 Si3N4 ZrO2 Ceramic Rollers for Laboratory Triple Three Roll Mill:

High hardness

High hardness

No pollution

No pollution

Great chemical inertness

Great chemical inertness

Long serice life

Long serice life

Wear & Corrosion resistant

Wear & Corrosion resistant

High using temperature

High using temperature