▼ Introduction of Ceramic Plungers

Ceramic plungers perform very well in wear-resistance, high temperature, saltwater, chemical, and metering applications. At UNIPRETEC, the ceramic materials we provides for waterjet cutting system is yttria stabilized Zirconia (ZrO2), which enable for a minimum Ra 0.05um surface polish, thereby improving packing life. Following are the typical features of zirconia ceramic as plungers:

√ Never Rust

|

√ Long Service Life

|

√ Chemical Inertness

|

√ Low Thermal Expansion

|

√ High Working Temperature

|

√ High Hardness (Mohs 8.0-9.0)

|

UNIPRETEC can provide ceramic plungers made from tough zirconia in combination of metal, such as stainless steel 316L or 304L, depending on the customer's specifications. We can bond the zirconia ceramic body to the stainless steel adapter for very dependable performance and extended field life. Zirconia Ceramic plungers developed by UNIPRETEC are available in both solid and hollow ceramic shapes. Ceramic plungers are unique in their performance when corrosion and abrasion resistance as well as longer packing life are required.

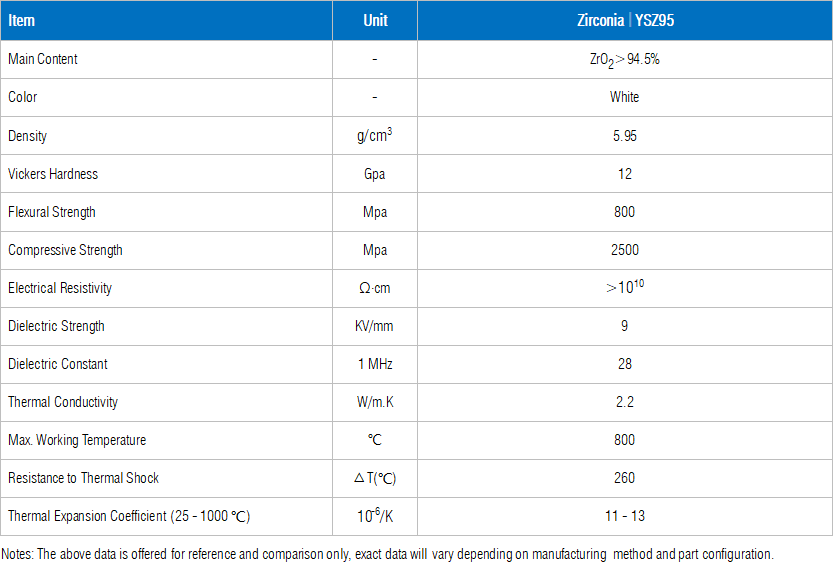

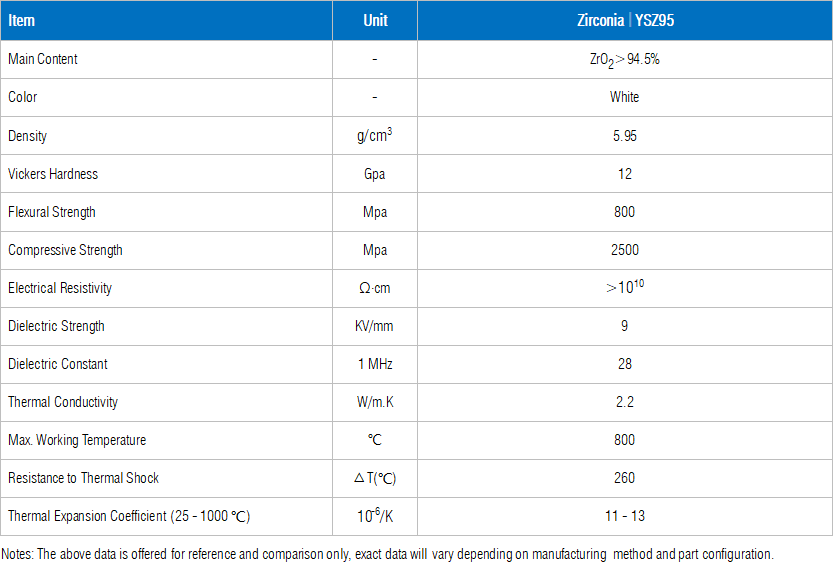

▼ Material Properties of Zirconia Plungers

▼ Application Environment

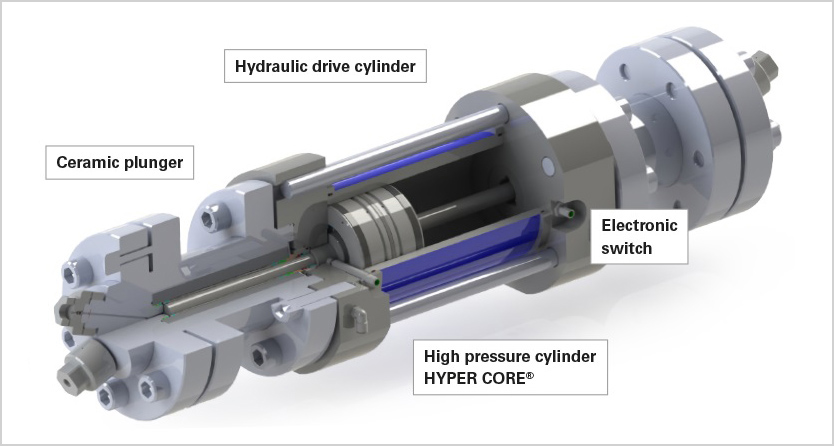

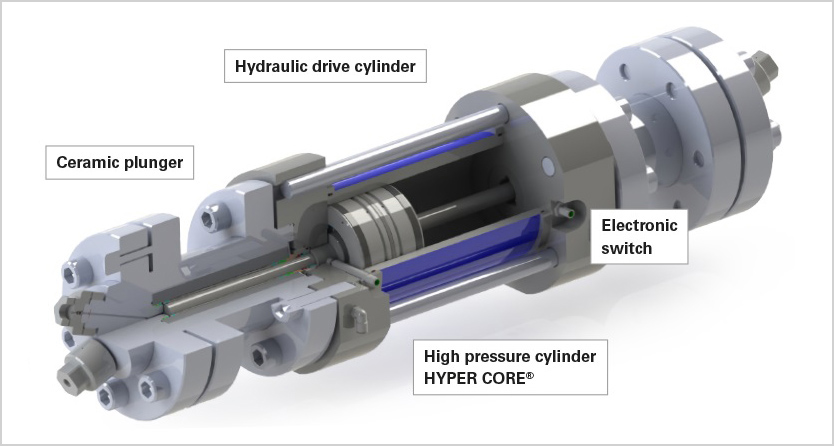

The plungers are the two smaller diameter shafts that are connected to each side of the piston. The attachment point is inside of the hydraulic cylinder. The other ends of the plungers extend into the left and right high pressure cylinders. Seals are placed around the plunger shaft to keep oil from seeping into the water side of the pump, and vice versa. The plungers from UNIPRETEC are made out of zirconia ceramic. Zirconia ceramic is used because of its ability to handle wear, heat and high pressure with little thermal expansion.