▼ Description of Alumina Ceramic Pistons

The ceramic piston plungers for high pressure washers are made using a high-performance alumina ceramic material that possesses high hardness, wear resistance, high temperature resistance, and corrosion resistance, ensuring consistent material performance. The microporous structure of the ceramic piston working surface provided by the unique processing technology has a self-lubricating effect, which alters the sliding friction and lubrication mechanism of the conventional piston pump. The surface of ceramic piston plungers is polished to a mirror finish using an advanced high-precision internal and exterior cylindrical grinder, and then assembled with the remaining components. It is quite convenient to operate when it has to be cleaned or replaced.

The world's most recognized high-quality pumps, such as the American CAT and the Italian INTERPUMP crankshaft pumps, both have fully solid ceramic pistons. These firms invented piston pumps. Years of practice have resulted in the adoption of ceramic pistons. As can be shown, ceramic pistons for high pressure cleaner are both correct and popular.

▼ Features of Ceramic Piston Plunger

High Corrosion Resistance High Corrosion Resistance

|

Good Thermal Conductivity Good Thermal Conductivity

|

High Hardness, Wear Resistant High Hardness, Wear Resistant

|

Excellent Electrical Insulation Excellent Electrical Insulation

|

Low Cost Fine Ceramic Material Low Cost Fine Ceramic Material

|

Maximum Using Temp. 1,650 °C Maximum Using Temp. 1,650 °C

|

▼ The Suitable Pump Models

● For Turbo and Boxjet Models: 15, 19, 21, 8-70, 8-90, 10-100, 11-50, 11-70, 11-120, 13-90

|

● TP Pump: TP2520J34, TP2526J34, TP2530J34 TT9071 & TP2533J34, Series 51 Pumps

|

● For Big Bang and Formula 99 Models: F-122, F-124, X-117S, X-161, X-220S, X-230, X-240S

|

● For Interpump Pump: W1507, WW55, WW56, WW74, WW75, WW90, WW93, WW94, WW95, WW906, WW907, WW909, WW1508, WW1509, WW1510, WW1511, WW1513

|

● For General Pump: T1508, TT551, TT561, TT741, TT751, TT901, TT931, TT941, TT951, TT1508, TT1510, TT1511, TT1512, TT1513, TT9061, TT9071, TT9091, TT2028, TT2035E, TT2035G

|

▼ Material Data Sheet of Ceramic Pistons (A990)

ITEM

|

UNIT

|

ALUMINA | A990

|

Main Content

|

-

|

99% Al2O3

|

Color

|

-

|

White & Ivory

|

Density

|

g/cm3

|

> 3.85

|

Vickers Hardness

|

Gpa

|

17

|

Flexural Strength

|

Mpa

|

360

|

Compressive Strength

|

Mpa

|

2,500

|

Electrical Resistivity

|

Ω·cm

|

>1014

|

Dielectric Strength

|

KV/mm

|

17

|

Dielectric Constant

|

1 MHz

|

9

|

Thermal Conductivity

|

W/m.K

|

29

|

Max. Working Temperature

|

°C / °F

|

1,650 / 3,000

|

Resistance to Thermal Shock

|

△T(°C)

|

230

|

Thermal Expansion Coefficient (25 - 1,000 °C)

|

10-6/K

|

7 - 9

|

∆ The data is offered for reference only, exact data will vary depending on producing method & part configuration.

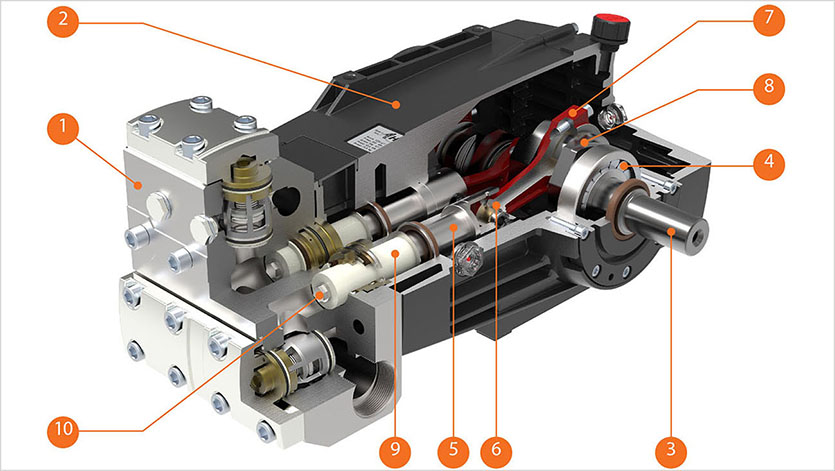

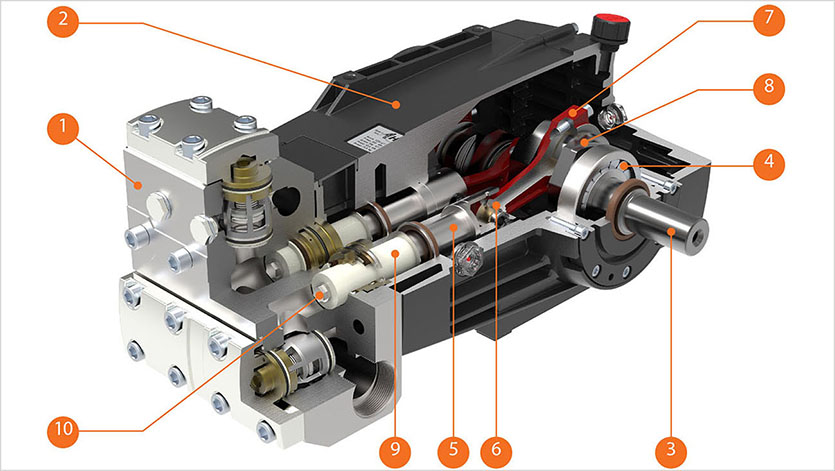

▼ Application of Alumina Piston (No. 9)

The high-pressure piston pump is the heart of the high-pressure washer, and because the plunger or piston is the most readily worn component in the movement, its quality has a direct impact on the machine's performance. Pistons for pressure washers can be classified into three broad categories based on their material composition: metal pistons, ceramic pistons, and ceramic coated pistons. At the moment, the majority of pistons used in medium and high-end machines are ceramic pistons and ceramic coated pistons.

Several of these high-pressure cleaners use ceramic-coated plungers. Ceramic coated plungers will undoubtedly outperform metal plungers due to the fact that their surface is likewise made of advanced ceramic. There is a widespread belief in the market that the ceramic coated plunger is an enhanced version of the solid ceramic plunger and thus superior to ceramic plungers, but this is not true. Additionally, there are numerous issues with ceramic coated plungers. After extended usage, the ceramic coated plunger will easily cause water to accumulate in the fuel tank, turning the oil in the crankcase into a white turbid liquid, increasing friction and shortening the life of the entire pump. Furthermore, the ceramic coated plunger cannot withstand excessively high pressure, and the coating is easily peeled off. After the coating is removed, friction increases, resulting in damage to the water and oil seals, as well as frequent water and oil leakage issues. Finally, if the ceramic coated plunger is damaged, it must be replaced in its whole, increasing the cost and difficulty of maintenance.