Alumina ceramics are widely used ceramics. Because of its superior performance, it has been more and more widely used in modern society, meeting the needs of daily use and special performance. Alumina ceramics are currently divided into two types: high-purity type and ordinary type.

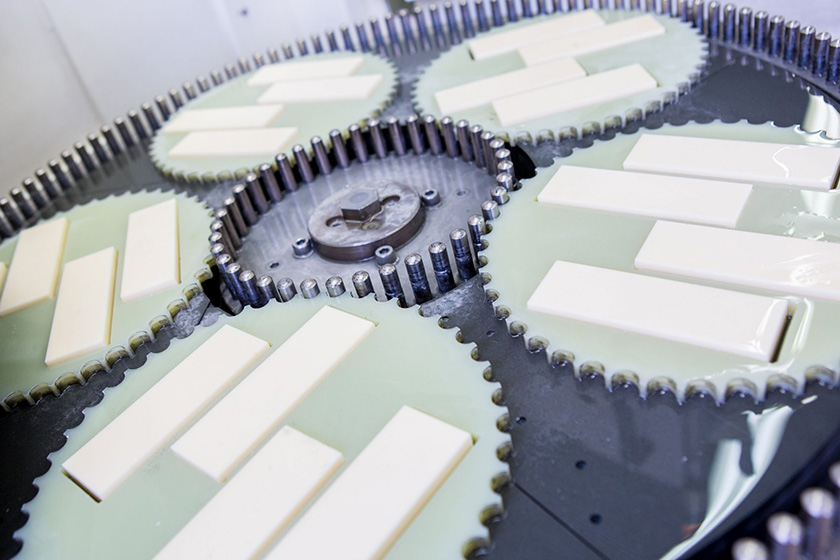

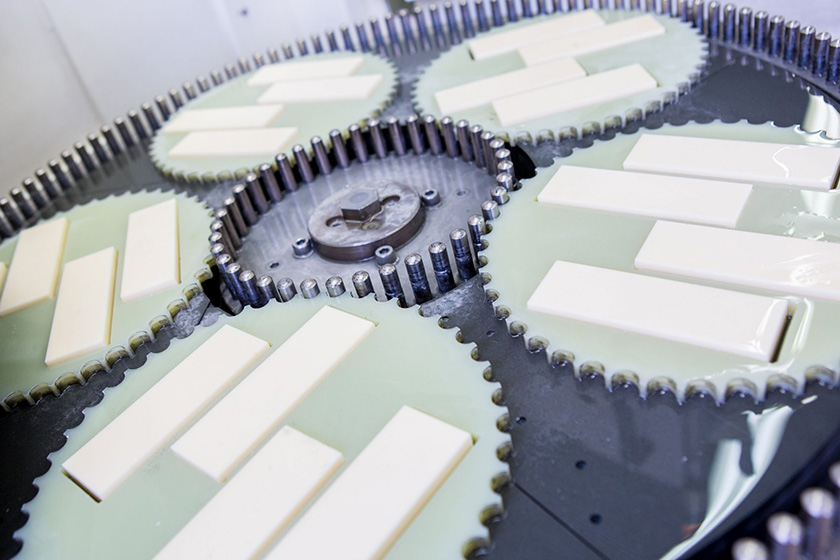

After sintering and cooling, It is not the end of product processing. Some products still cannot meet application requirements. Therefore, they need to be processed, such as size correction and polishing. The following will introduce the polishing method of alumina ceramics, as follows:

1. Using laser processing and ultrasonic processing, grinding and polishing.

2. Grind and polish with Al2O3 powder or diamond abrasive paste.

3. It is necessary to use glazing method for products with high surface finish requirements.

4. The surface of the material is treated by ion implantation. Ion implantation of ceramic is a supplement to the existing toughening mechanism and is a deep processing of the prepared ceramic products.

5. Because the hardness of alumina ceramic material is relatively good, use tools like diamond, silicon carbide, B4C, etc. harder than alumina to grind from coarse to fine step by step, which also improves the lubricity of alumina ceramic material surface in advance during the polishing process.