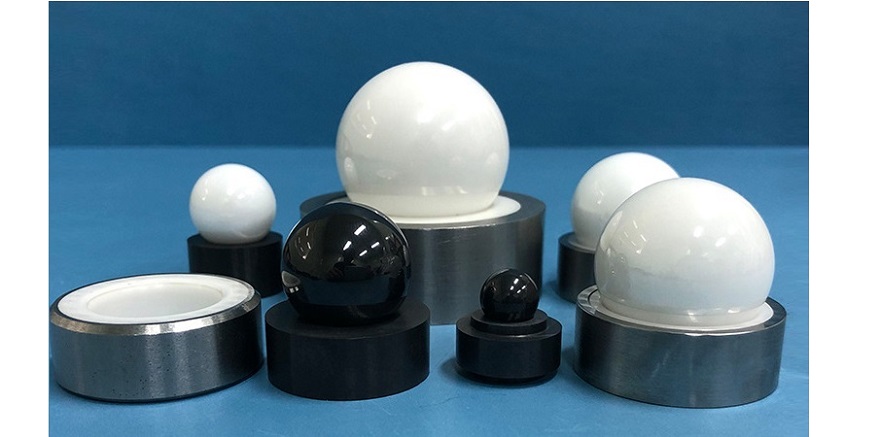

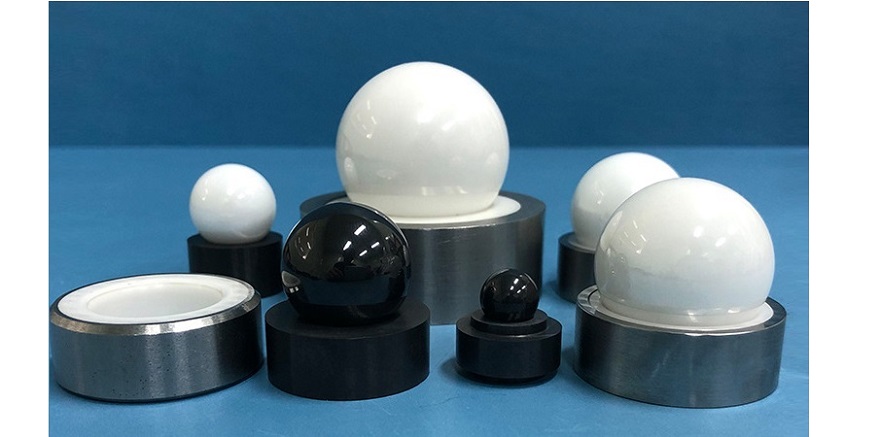

1. All parts in contact with the medium are made of structural ceramic materials, whose chemical stability and hardness (Rockwell hardness HRC90) are second only to diamond. Therefore, it has excellent wear resistance, corrosion resistance, erosion resistance, good heat insulation and small thermal expansion.

2. The ball is manufactured by advanced grinding equipment and technology, with high precision of ball roundness and good surface finish. After grinding with the valve seat, the self-lubricating property of Zr02 ceramics can be used to obtain good sealing performance.

3. The contact surface of the valve ball and valve seat is processed with precise grinding technology and advanced mechanical equipment manufacturing, so that the inner R and outer R of the ball and seat are closely combined, the ball size precision is high, the surface roughness is good, and the torque of the whole valve is light, the resistance is small, and the sealing performance reaches zero leakage.

4. Completely changed the shortcomings of metal hard-sealed ball valve, such as easy leakage, large torque, and non-corrosion-resistant sealing surface.

5. The good wear resistance of ceramics makes the valve durable, reliable, and has a long service life, which is 2-4 times that of titanium alloy valves and Monel valves.

6. Suitable for high hardness granular media, or media with soft particles but corrosive.

7. Application areas: thermal power plants, steel, petroleum, chemical, paper, biological engineering, and other industries. It is suitable for conveying boiler steam, lime slurry, seawater containing particles, high hardness particles, corrosive media containing soft particles, powder, flue gas desulfurization, ash discharge, slag discharge, and water supply treatment. Change the material according to the purpose, and can be used in different temperatures and media.

Solar polysilicon valve (used for: gas conveying silicon powder) In the transportation of silicon powder, the ball is easily wrapped by silicon powder, and frequent opening is easy to damage the metal seal, resulting in leakage and other problems. Due to the high hardness of silicon powder, the general Ball valve service life is very short. In view of this situation, we have specially researched and developed a suitable silicon powder conveying ceramic valve, using the strong corrosion resistance of structural ceramics and the high corrosion resistance material of zirconium alloy, so that the service life of the new valve is 6 times higher than that of the original valve. The equipment management of solar polysilicon fume delivery brings an exciting good news!