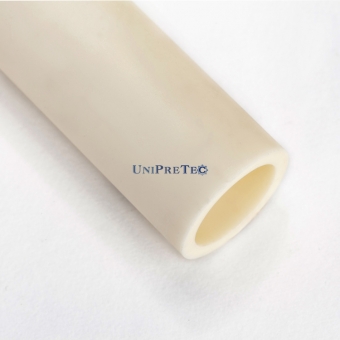

▼ Material Description of Alumina Tubes

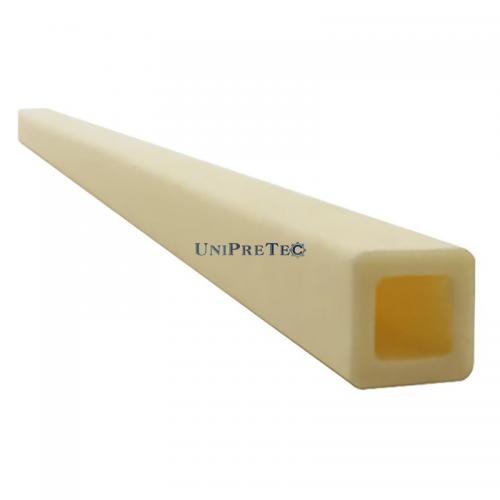

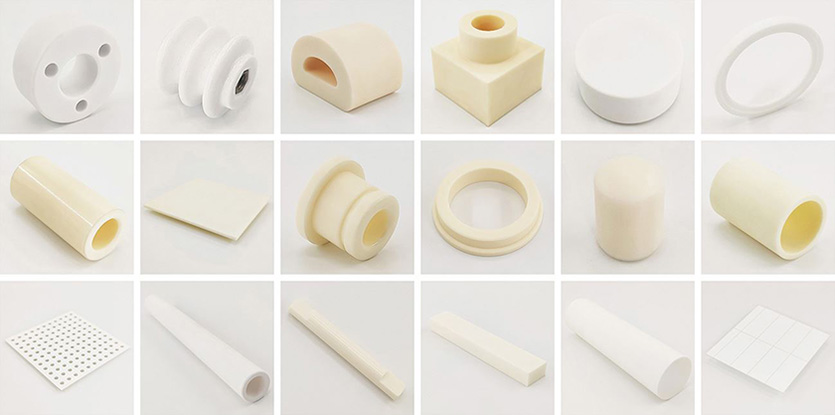

Alumina ceramic tube is made of Aluminum Oxide(Al2O3), which is a white or ivory white ceramic that has been applied to electrical components from an early stage by taking advantage of its good electrical insulation properties, besides, ceramic tubes made of high alumina have also high resistance to temperature, heat, wear and corrosion, and alumina ceramic is the cheapest material among the fine technical ceramics. UNIPRETEC offers high alumina tube with a purity range from 90% to 99.8%. It is also possible to manufacture large nonporous alumina ceramic tubing, and the high purity type has high mechanical strength and excellent corrosion resistance.

√ High Hardness

|

√ Low Coefficient of Thermal Expansion

|

√ Excellent Electrical Insulator

|

√ Mechanically Stable at High Temperature

|

√ Good Thermal Shock Resistance

|

√ High density, non-porous and vacuum tight

|

√ Resists Abrasive Wear and Chemical Attack

|

√ ......

|

▼ Material Properties of Alumina Tube

ITEM

|

UNIT

|

ALUMINA | A950

|

ALUMINA | A990

|

Main Content

|

-

|

95% Al2O3

|

99% Al2O3

|

Color

|

-

|

White

|

White & Ivory

|

Density

|

g/cm3

|

> 3.65

|

> 3.85

|

Vickers Hardness

|

Gpa

|

14

|

17

|

Flexural Strength

|

Mpa

|

310

|

360

|

Compressive Strength

|

Mpa

|

2,200

|

2,500

|

Electrical Resistivity

|

Ω·cm

|

>1014

|

>1014

|

Dielectric Strength

|

KV/mm

|

15

|

17

|

Dielectric Constant

|

1 MHz

|

8

|

9

|

Thermal Conductivity

|

W/m.K

|

25

|

29

|

Max. Working Temperature

|

°C / °F

|

1,500 / 2,730

|

1,650 / 3,000

|

Resistance to Thermal Shock

|

△T(°C)

|

210

|

230

|

Thermal Expansion Coefficient (25 - 1,000 °C)

|

10-6/K

|

7 - 9

|

7 - 9

|

∆ The data is offered for reference only, exact data will vary depending on producing method & part configuration.

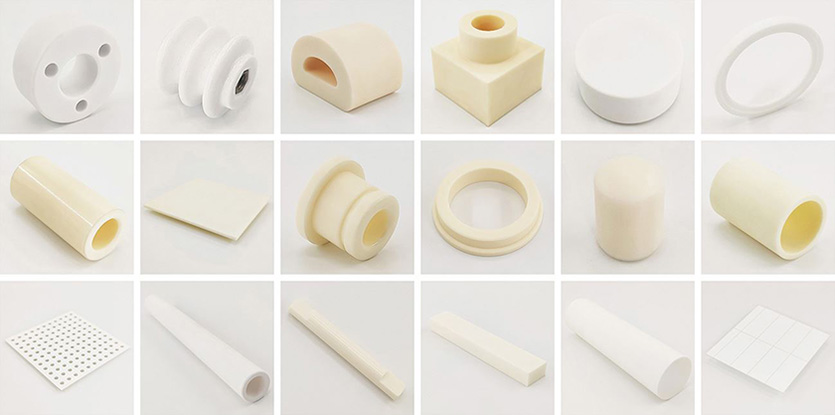

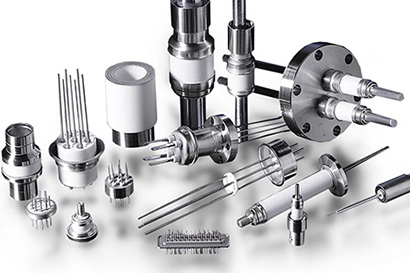

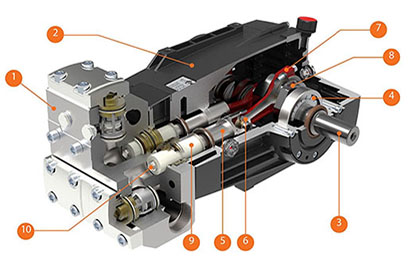

▼ Typical Applications of Aluminum Oxide Tubes

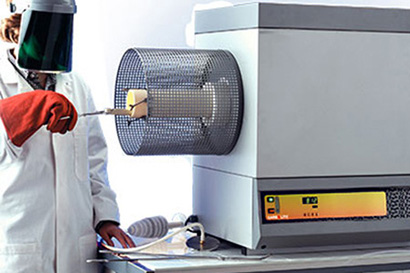

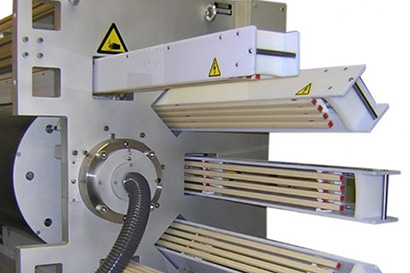

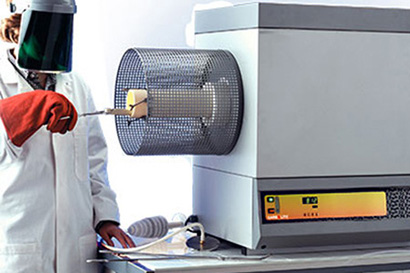

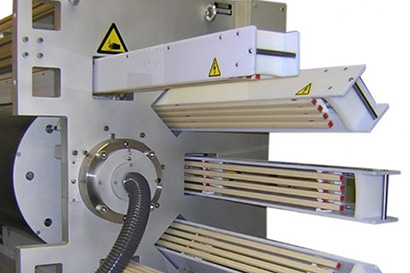

- Noble metal thermocouple protection, furnace tubes, high temperature vacuum furnaces, heat treating furnace rollers, radiant tubes, laser tubes, corona treater tubes and ozone generators.

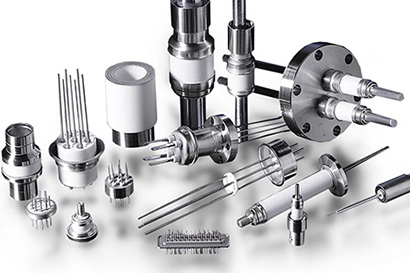

- Corrosive environments and electrical insulation applications. Noble metal thermocouples and diffusion furnace profile couples, laser wave guides and RTD's.

- Solutions for the pharmaceutical, food and cosmetic industries with a focus on filling, dosing and control applications.

|

Heating Tube for Tube Furnace

|

Tube for Corona Treatment

|

|

Electrical Insulator Tube

|

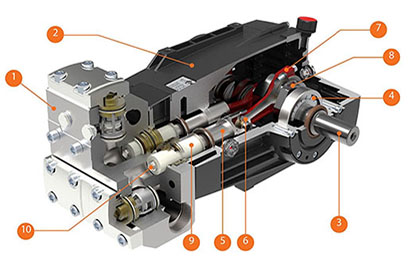

Wear Liner Tube for Pumps

|

|

Thermocouple Protection Tubes

|

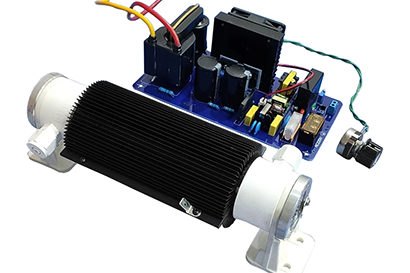

Tube for Ozone Generator

|