HBN - Hot Pressed Hexagonal Boron Nitride has the same type of layer structure as graphite and provides a very good lubrication/mold-release characteristic. Boron Nitride Ceramic is stable up to approximately 2000°C in the inert atmosphere and 900°C in the air. Besides, Boron Nitride is stable against most organic solvents and corrosive chemicals, and unwettable by most molten metals and glasses. Hexagonal Boron Nitride has high electrical insulation and voltage resistance at high temperature and no changes in permittivity and dielectric loss up to high-frequency area. What's more, because of high thermal conductivity and high heat radiation, hot pressed BN can be applied to various heat radiators.

Properties of Hot Pressed Hexagonal Boron Nitride BN:

Low density Low density

|

Excellent Machinability Excellent Machinability

|

Good chemical inertness Good chemical inertness

|

High electrical resistivity High electrical resistivity

|

High thermal conductivity High thermal conductivity

|

High temperature material High temperature material

|

Excellent thermal shock resistance Excellent thermal shock resistance

|

Excellent lubricating properties Excellent lubricating properties

|

High dielectric breakdown strength High dielectric breakdown strength

|

Non-wetted by molten metal & glass Non-wetted by molten metal & glass

|

With all the properties, boron nitride setter plate/ boron nitride box is a perfect choice for firing/ sintering Silicon Nitride(Si3N4) substrate and Aluminum Nitride(AlN) substrate.

Applications of Hot Pressed Hexagonal Boron Nitride BN:

CVD crucibles CVD crucibles

|

Microwave tubes Microwave tubes

|

Low friction seals Low friction seals

|

Sputtering targets Sputtering targets

|

Plasma arc insulators Plasma arc insulators

|

Microcircuit packaging Microcircuit packaging

|

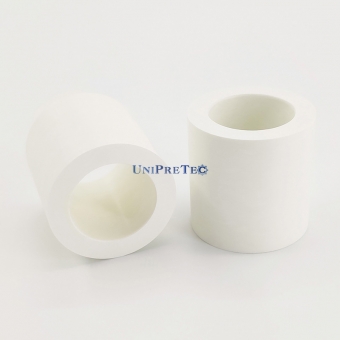

Vacuum melting crucibles Vacuum melting crucibles

|

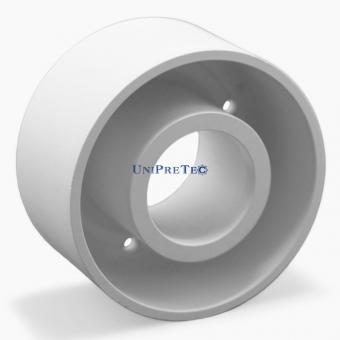

Horizontal continuous casting break rings Horizontal continuous casting break rings

|

High temperature furnace fixtures and supports High temperature furnace fixtures and supports

|

High precision sealing, brazing, and metallizing fixtures High precision sealing, brazing, and metallizing fixtures

|

Boron doping wafers in silicon semiconductor processing Boron doping wafers in silicon semiconductor processing

|

Electronic parts(heat sink, substrate, coil form, prototype) Electronic parts(heat sink, substrate, coil form, prototype)

|

More Information About Boron Nitride

Hexagonal Boron Nitride (white graphite) is a loose, lubricating, moisture-absorbing white powder with density 2.27/cm3, Mohs hardness 2, and low mechanical strength, but higher than graphite. No obvious melting point, sublimate at 3000℃ in 0.1Mpa nitrogen atmosphere. The operating temperature in nitrogen or argon is 2000°C. And in oxygen atmosphere, stability is poor, operating temperature is below 1000°C.

Hexagonal Boron Nitride has low expansion coefficient and high thermal conductivity, so it has excellent thermal shock resistance, and it will not be damaged even after hundreds of times of cycle use at 1200-20°C. The expansion coefficient of BN is equivalent to that of quartz, but the thermal conductivity is 10 times that of quartz.

Hexagonal Boron Nitride is a good conductor of heat and a typical electrical insulator. The resistivity at room temperature can reach 1016~1018. Even at 1000℃, the resistivity is still 104~106Ω.cm. The dielectric constant of BN is 3~5, the dielectric loss is (2~8) *10-4, and the breakdown strength is twice that of Al2O3, reaching 30~40 Kv/mm. Hexagonal Boron Nitride has good lubricity and resistance oxidation, corrosion resistance, insulation, thermal conductivity and chemical stability. It can be used to make TiB2/BN composite ceramics, it can also be used for advanced refractory materials and super hard materials, break rings for horizontal continuous rolling steel, for high temperature resistant lubricants and high temperature coatings, and it is also the raw material for the synthesis of cubic boron nitride.

Hexagonal Boron Nitride has excellent chemical stability. It has neither wetting nor effect on most metal melts, such as steel, stainless steel, Al, Fe, Ge, Bi, Si, Cu, Sb, Sn, In, Cd, Ni, Zn, etc. Therefore, it can be used as a high-temperature galvanic couple protection cover, melting metal crucibles, utensils, pipes for conveying liquid metal, pump parts, cast steel abrasive tools and high-temperature electrical insulation materials. Using the heat and corrosion resistance of BN, high-temperature components, rocket combustion chamber linings, thermal shielding of spacecraft, and corrosion-resistant parts of magnetic flow generators can be manufactured.

Low density

Low density

Excellent Machinability

Excellent Machinability