▼ Introduction of Macor Grade Machinable Glass Ceramic

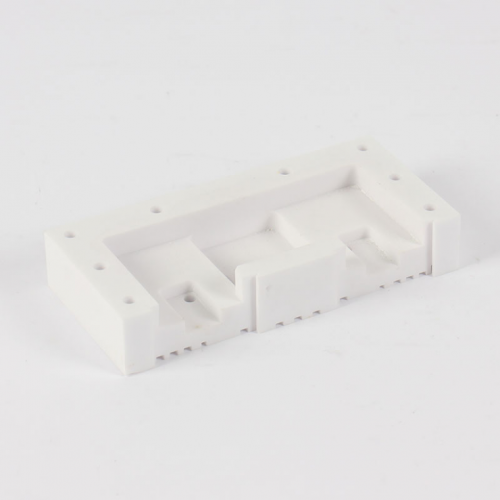

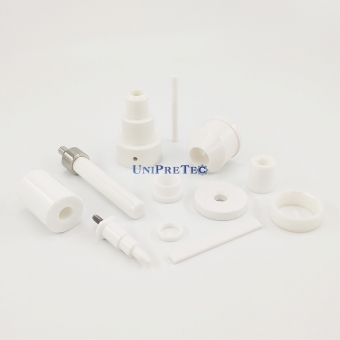

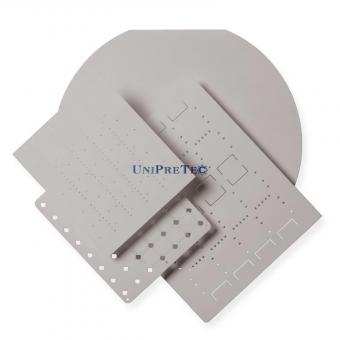

Macor Grade Machinable Glass Ceramic from UNIPRETEC is a white, odorless, porcelain-like (in appearance) material composed of approximately 55% fluorophlogopite mica and 45% borosilicate glass. Machinable glass ceramic is a new class of ceramic material which is capable of being machined to precise tolerances using conventional metal-working tools and equipment. There are a number of useful machining techniques which are pertinent to this material.

▼ Features of Macor Grade Machinable Glass Ceramic

√ high use temperature (800°C continuous; 1,000°C peak);

|

√ low thermal conductivity and it is a useful high temp. insulator;

|

√ it can be thick or thin film metallized, brazed, epoxy and frit bonded;

|

√ it is strong and rigid. It unlike high temperature plastics will not creep or deform;

|

√ it is radiation resistant and plays a key role in nuclear applications and nuclear-related R&D;

|

√ it is white and can be highly polished. It is the perfect material for medical and optical devices;

|

√ excellent electrical insulator and it is used throughout the semiconductor and electronic industries;

|

√ no porosity and when properly baked, it will not outgas. It is widely used in ultra high vacuum applications;

|

▼ Material Properties of Machinable Glass Ceramic

ITEM

|

UNIT

|

Value

|

Main Content

|

-

|

SiO2 + MgO + Al2O3 + K2O + B2O3 + F

|

Color

|

-

|

White

|

Density

|

g/cm3

|

2.35 - 2.40

|

Apparent Porosity

|

%

|

0.069

|

Mohs Hardness

|

-

|

4 - 5

|

Compressive Strength (25 °C)

|

Mpa

|

510

|

Flexural Strength (25 °C)

|

Mpa

|

90

|

Thermal Conductivity (25 °C)

|

W/m.K

|

1.43

|

Max. Using Temperature

|

°C

|

1,000

|

Continuous Using Temperature

|

°C

|

800

|

Thermal Expansion Coefficient (25 - 1,000 °C)

|

10-6/K

|

7.4

|

Electrical Resistivity (20 °C)

|

Ω·cm

|

9.0 x 1013

|

Electrical Resistivity (200 °C)

|

Ω·cm

|

5.9 x 1010

|

Electrical Resistivity (500 °C)

|

Ω·cm

|

2.3 x 108

|

Dielectric Constant (1 MHz)

|

-

|

5.7

|

Dielectric Strength (25 - 1,000 °C)

|

KV/㎜

|

43

|

Tangent of Dielectric Lose Angle

|

-

|

4.0 x 10-3

|

Chemical Stability (1:9 HCI, 1 hour)

|

mg/cm2

|

5.84

|

Chemical Stability (10% NaOH, 1 hour)

|

mg/cm2

|

12.40

|