▼ Description of Alumina Ceramics

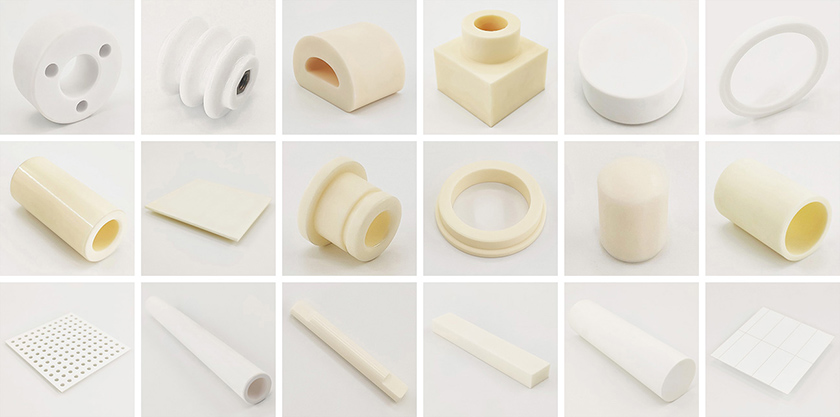

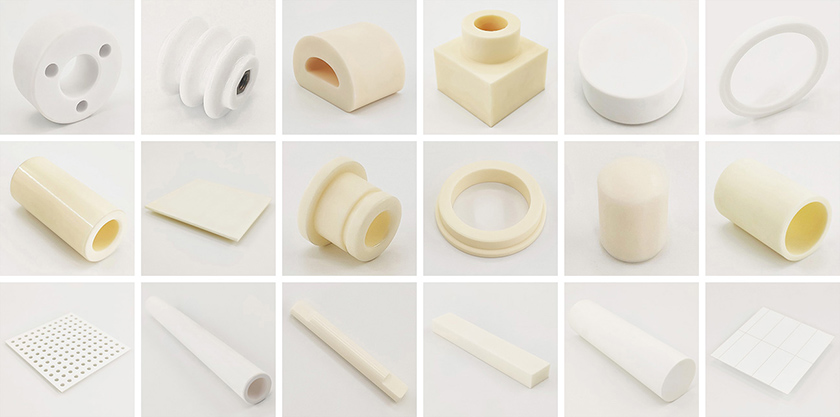

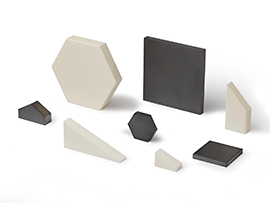

Alumina, or Aluminum Oxide, is a durable fine industrial ceramic that is commonly used in various applications. The purity of Al2O3 in finished alumina products usually ranges between 90 and 99.8%, UNIPRETEC mainly work with alumina materials with Al2O3 purity of 95 to 99 percent. Parts and components made of alumina ceramics have many favorable features as below.

Good Thermal Conductivity Good Thermal Conductivity

|

High Corrosion Resistance High Corrosion Resistance

|

Excellent Electrical Insulation Excellent Electrical Insulation

|

High Hardness, Wear Resistant High Hardness, Wear Resistant

|

Maximum Using Temp. 1,800 °C Maximum Using Temp. 1,800 °C

|

Low Cost Fine Ceramic Material Low Cost Fine Ceramic Material

|

With about 10 years of manufacturing alumina ceramic components, UNIPRETEC offers a variety of alumina ceramic forming methods, including molded injection, die pressing, slip casting, extrusion, and cold isostatistically pressing. We are also good at precision machining, since the hardness of sintered alumina ceramic parts is about 9 Mohs, only diamond tool is suitable for machining work.

▼ Material Properties of Aluminum Oxide Ceramics

ITEM

|

UNIT

|

ALUMINA | A950

|

ALUMINA | A990

|

Main Content

|

-

|

95% Al2O3

|

99% Al2O3

|

Color

|

-

|

White

|

White & Ivory

|

Density

|

g/cm3

|

> 3.65

|

> 3.85

|

Vickers Hardness

|

Gpa

|

14

|

17

|

Flexural Strength

|

Mpa

|

310

|

360

|

Compressive Strength

|

Mpa

|

2,200

|

2,500

|

Electrical Resistivity

|

Ω·cm

|

>1014

|

>1014

|

Dielectric Strength

|

KV/mm

|

15

|

17

|

Dielectric Constant

|

1 MHz

|

8

|

9

|

Thermal Conductivity

|

W/m.K

|

25

|

29

|

Max. Working Temperature

|

°C / °F

|

1,500 / 2,730

|

1,650 / 3,000

|

Resistance to Thermal Shock

|

△T(°C)

|

210

|

230

|

Thermal Expansion Coefficient (25 - 1,000 °C)

|

10-6/K

|

7 - 9

|

7 - 9

|

∆ The data is offered for reference only, exact data will vary depending on producing method & part configuration.

▼ Popular Alumina Ceramic Products

|

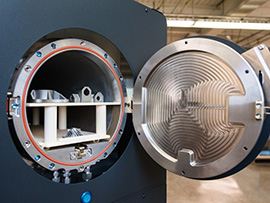

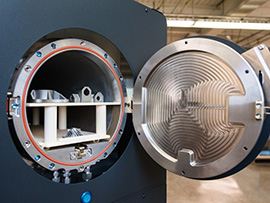

Trays and Setters for MIM Sintering

|

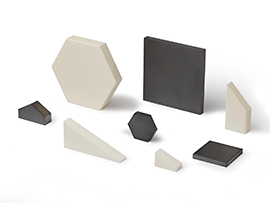

Armor Plates and Tiles

|

Wear Resistant Liners

|

|

Pump Plunger

|

Tubes and Rods for Thermocouple

|

Piston for Pressure Washer

|

|

Customized Precision Parts

|

Roller for Three Roll Mill

|

Ceramic Insulating Substrates

|