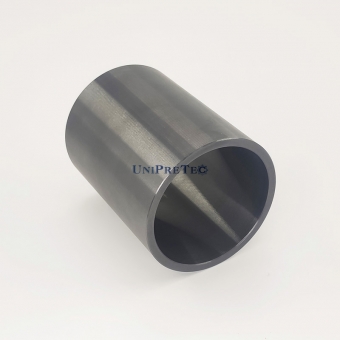

The heating rate of the pusher kiln generally depends on the external dimensions of the soft magnetic material product and the structure domain of the kiln. The general temperature rise and fall speed is 50~200℃/h. Because the combustion plate not only bears a certain load during the advancement process in the kiln, but also needs to be recycled from high temperature (1400~1500℃) to room temperature. It takes 20-40h for each cycle. Therefore, it is required to have a higher load softening temperature and mechanical strength, good seismic stability and creep resistance, and a longer service life. Production practice shows that the quality of the setter plate has a great influence on the qualification rate of soft magnetic materials. To make the qualified rate of soft magnetic materials reach a higher level, the use of good performance setter plates is a necessary prerequisite.

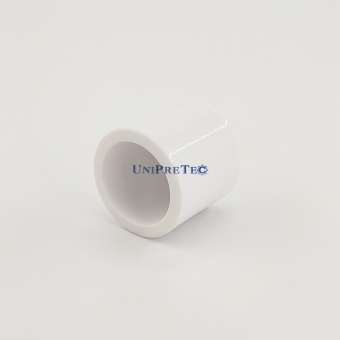

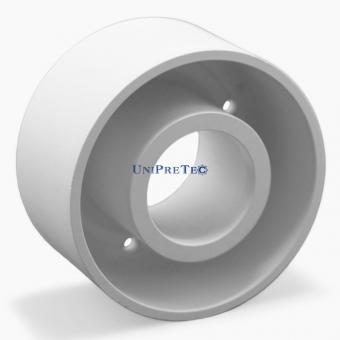

Selecting high-quality raw materials as aggregates, through particle grading and production process tests, a setter plate with good use effect and long life has been developed. The determination of the material takes into account the harsh use conditions of the setter plates. The selected material not only has the characteristics of high strength, good thermal shock stability, and strong creep resistance, but also has no pollution to the fired product. After repeated selection and comparison, the corundum mullite material is determined to be the ideal material for the setter plate to be developed.

Natural mullite is rarely synthesized artificially. Because mullite has good high-temperature mechanical and high-temperature thermal properties, synthetic mullite and its products have higher density and purity, lower thermal conductivity and thermal expansion coefficient, high-temperature structural strength, and low-temperature creep rate. It has the advantages of strong thermal shock resistance and chemical corrosion resistance and high melting point. Corundum has good elasticity, high melting point, good wear resistance, chemical resistance and volume stability at high temperatures, high hardness and high refractoriness. In addition, mullite crystals are generally columnar or prismatic, and corundum crystals are generally granular. The mullite and corundum are combined in a certain ratio to form a corundum-mullite composite material. According to the mechanism of compound modification, the corundum-mullite composite material is formed. According to the mechanism of multi-phase modification, the difference in thermal expansion coefficient between corundum crystal and mullite crystal is used to generate microcracks at the particle interface to make it have microcracks. The toughening mechanism improves the thermal shock resistance of the material. At the same time, the high temperature strength and creep resistance of the composite material are better than those of pure mullite or corundum materials. Since mullite and corundum have the above-mentioned excellent properties and are not easy to react with the products they are burned, the corundum mullite material can meet the requirements of the magnetic material kiln.