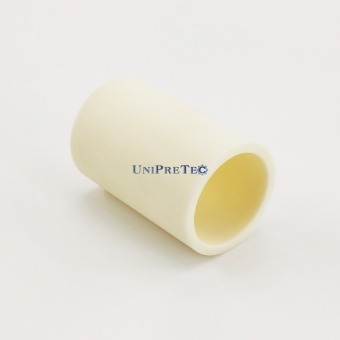

The theoretical melting point of magnesium oxide ceramics is as high as 2800℃, and it can work stably in the temperature of 2400℃ under the protection of oxidizing atmosphere or nitrogen. The theoretical density is 3.56~3.65g/cm3, the Mohs hardness is 5-6. The resistance value is high, and there is good electrical insulation. Moreover, the ability to resist alkaline metal slag is extremely strong, has excellent thermo-chemical properties and stability against metals, and is especially suitable for some harsh occasions with high temperature and alkaline corrosive substances where ceramic materials such as alumina cannot meet the conditions, such as smelting of non-ferrous metals and precious metals. It can also be used to smelt high-purity radioactive metal uranium, thorium alloy, iron and its alloys.

Because of its strong resistance to alkaline metal slag, magnesium oxide crucible products have many advantages:

1. High temperature resistance, good corrosion resistance, its theoretical using temperature is as high as 2200℃, and it can be used for a long time at high temperature of 1600℃~1800℃. Its high temperature stability and corrosion resistance are better than alumina ceramics.

2. Strong resistance to alkali metal slag, excellent thermo-chemical properties and stability against metals.

3. With high purity, it can effectively avoid contamination of the loaded metals at high temperatures.

Application of Magnesium Oxide Crucibles:

1. Crucibles and other refractory materials for steel, glass and other smelting industries under corrosive conditions. The operating conditions of the steel-making industry are very harsh: the operating temperature is between 1500 and 1700°C, and there is corrosion of molten metal, slag, iron oxide, dust and gas. The conditions of the glass industry and the steel-making industry are similar: the operating temperature is between 1100 and 1700°C.

2. Crucible for smelting metals and alloys, such as nickel alloy, radioactive metal uranium, thorium alloy, iron and its alloys, etc.

3. Piezoelectric, superconducting materials, etc., no pollution, lead corrosion resistance, etc.

4. Ceramic sintered carrier. Especially for the sintering protection of ceramic products with corrosive and volatile substances at high temperatures, such as β-Al2O3.