High Purity Al2O3 Alumina Ceramic Sintering Trays and Setter Plates

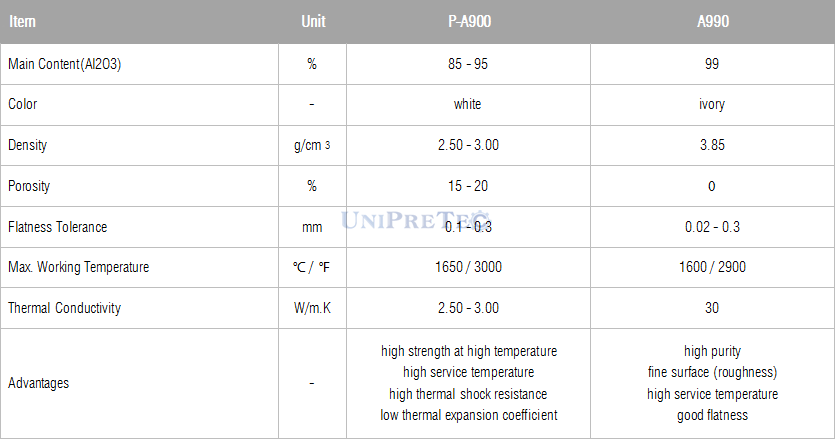

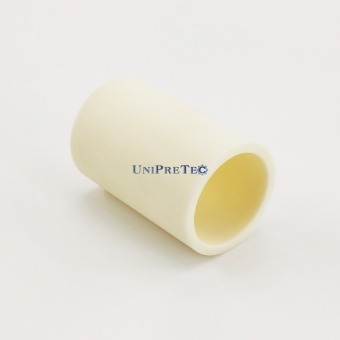

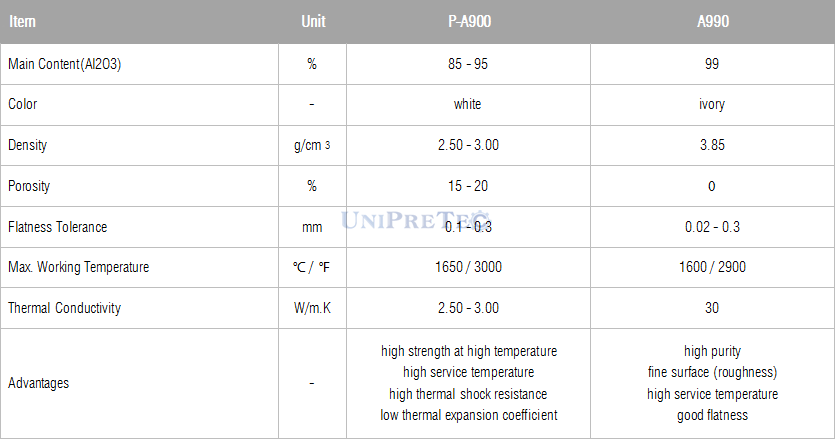

There are two main materials of Ceramic Kiln Furnitures by UNIPRETEC: A990 and P-A900.

A990 is high dense alumina ceramic with 99% Al2O3, ceramic trays/setter plates made of A990 can be fine grinded in order to provide good flatness and surface roughness.

P-A990 is porous ceramic with the main content - Al2O3,

Advantages of Sintering Trays Made of High Purity Al2O3 Alumina Ceramics

Applications of Ceramic Sintering Trays, Setter Plates and Saggers

|

>>> Fuel Cell Material Setters

|

>>> Electronics Parts Sintering

|

>>> Aerospace Materials Sintering Trays

|

>>> Solid Oxide Fuel Cell (SOFC) Components

|

>>> Powdered Metals Sintering (PM Sintering)

|

>>> Low Temperature Co-fired Ceramics (LTCC)

|

>>> Technical Ceramics Injection Molded Parts (CIM Components)

|

>>> Alumina Ceramic Parts Sintering (Aluminum Oxide Components Sintering)

|

>>> Zirconia Ceramic Parts Sintering (Zirconium Oxide Components Sintering)

|

>>> Metal Injection Molded Parts Sintering (MIM Components Sintering)

|

|

>>> Powder Injection Molded Parts Sintering (PIM Components Sintering)

|

Technical Materials Properties of Alumina Ceramic Sintering Trays/Setter Plates/Saggers

Manufacturing Processes of Al2O3 Alumina Ceramic Sintering Trays and Setter Plates