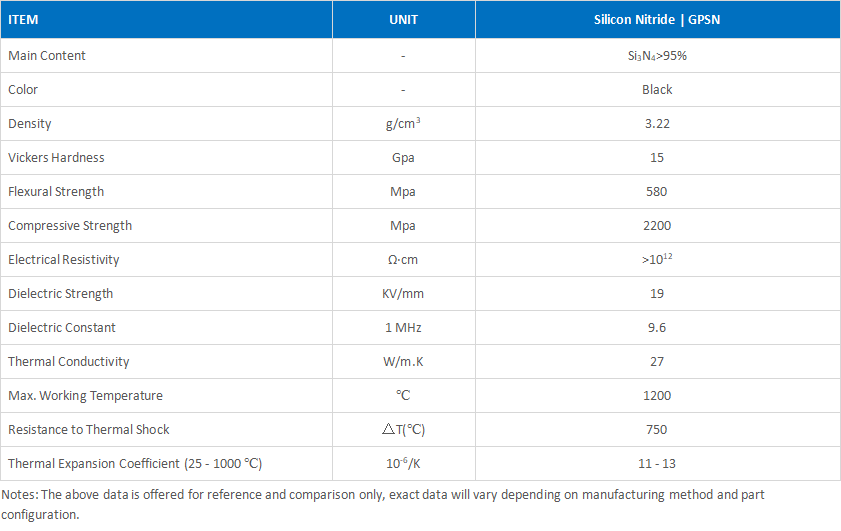

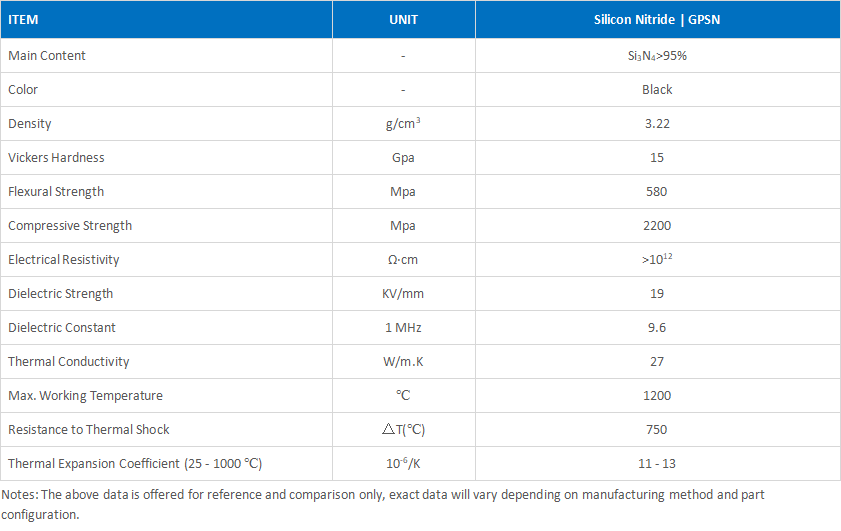

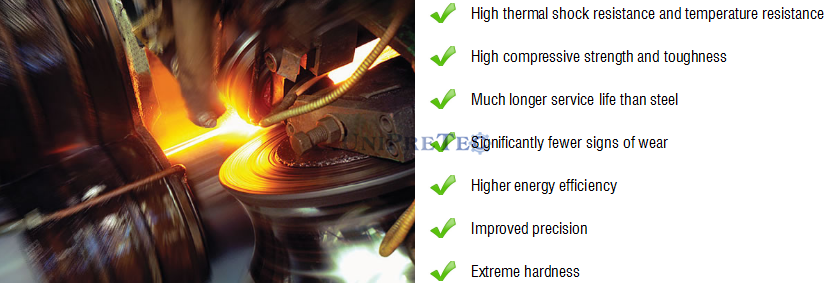

Ceramic Si3N4 Welding Rolls for Steel Tube Industry

Silicon nitride ceramic welding rolls are used in the metal wire and coil processing industry, and can be used for guiding, extrusion, rolling, stretching and other processing of various metal bars, tubes, wires, and special-shaped materials.

What are the main advantages of silicon nitride materials in the field of welding?

-In the field of welding, the biggest performance advantage of silicon nitride ceramic materials is non-magnetic, non-conductive, low thermal expansion coefficient and high hardness. Since silicon nitride ceramics are non-magnetic and non-conductive, the high-frequency electric energy is more concentrated on the welding and the welding quality is improved. When welding, the welding rolls must be in contact with the welding material. If the welding roll is conductive, it will affect the location and range of the high-frequency current flow path, which will affect the high-frequency heating and further affect the product welding.

-Low thermal expansion coefficient is another prerequisite to ensure stable product quality. The welding process itself is a process of rapid cooling and heating. Any material will inevitably undergo thermal expansion and contraction. If the welding roll is heated to expand and deform, it is good for welding thicker materials, if the thickness of the processed material is too thin, otherwise, it may lead to unqualified product quality or poor product welding. However, the use of silicon nitride welding rolls can well avoid these problems, because silicon nitride ceramics has a low thermal expansion coefficient, which ensures that even in the case of rapid cold and rapid heat, the welding accuracy is still very good, and the stability is benefit for product quality.

-Silicon nitride is harder than steel, more wear-resistant, and can withstand higher temperatures. Silicon nitride also has great thermal shock resistance, oxidation resistance, and does not react with metal workpieces. therefore,

1. Silicon nitride welding rolls have longer service life. It is more than 10 times that of the stainless steel rolls, and is 2 to 3 times longer than that of tungsten carbide rolls.

2. Silicon nitride welding rolls can work at a high temperature of 1000°C, while steel welding rolls generally has a maximum operating temperature of 300°C.

3. The surface finish of silicon nitride welding roll is better.

4. No undesirable phenomena such as garlanding.

5. Good accuracy and consistency.

6. Reduce the scrap rate.

7. Reduce the defect parts.

8. Increase production efficiency.

Despite all the advantages, silicon nitride ceramic welding rolls also has its own shortcomings. On one hand, due to the high cost of the material and the material itself is not conductive, it can only be processed slowly by a precision grinder, which leads to the problem of the silicon nitride ceramic rolls. The cost is several times that of ordinary mold steel rolls. On the other hand, in view of the characteristics of the material itself, silicon nitride is a hard and brittle material, which has higher requirement on working environment, so pay more attention when using it.