Material Introduction

The purity of the zirconia crucible is 99.9%, the density is 6.00g/cm3, and the maximum operating temperature is 2400℃. Mainly used in smelting precious metals, with good thermal stability.

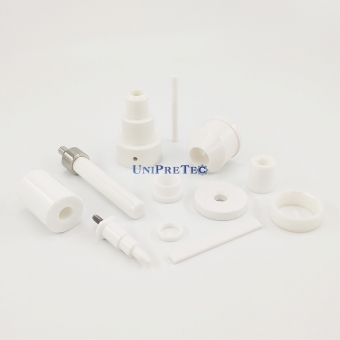

Main purpose: melting precious metals, such as melting gold, silver, platinum, rhodium, different alloys and mixed metals (recycling). Zirconia crucible has good high temperature stability and is an ideal experimental high temperature refractory product. Its thermal conductivity is poor, but its electrical conductivity and corrosion ability are very strong. Even if it is heated to more than 1,900 degrees Celsius, it will not interact with molten aluminum, iron, nickel, platinum and other metals, silicates and acid slag. Therefore, it can be used to make crucibles for smelting precious metals, refractory tubes, heat-resistant glass and heat-resistant enamel, etc. Incorporating white zirconium dioxide into ceramics can make the ceramics whiter, brighter, more heat-resistant, and have increased strength. The use of this type of ceramics to make high-temperature insulating porcelain bottles has strong insulation capacity and a small thermal expansion coefficient.

zirconia is not suitable for use in inductive heating and has a low thermal shock resistance, so only slow heating curves can be run with this material. Slow heating and slow cooling is advisable.

Material Advantages

High hardness High hardness

|

High fracture toughness High fracture toughness

|

Good chemical inertness Good chemical inertness

|

Long service life (Cost-effective) Long service life (Cost-effective)

|

High wear & corrosion resistance High wear & corrosion resistance

|

High working temperature High working temperature

|

CTE in range of steel CTE in range of steel

|

... ...

|

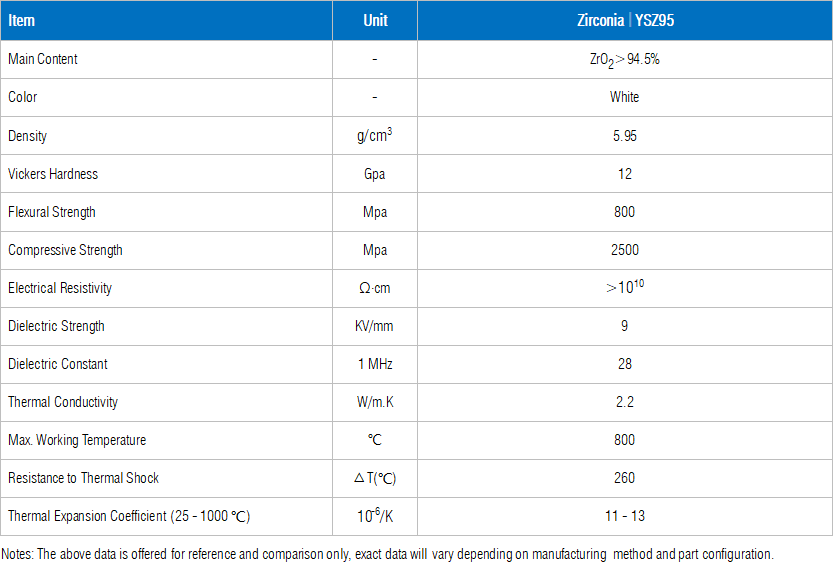

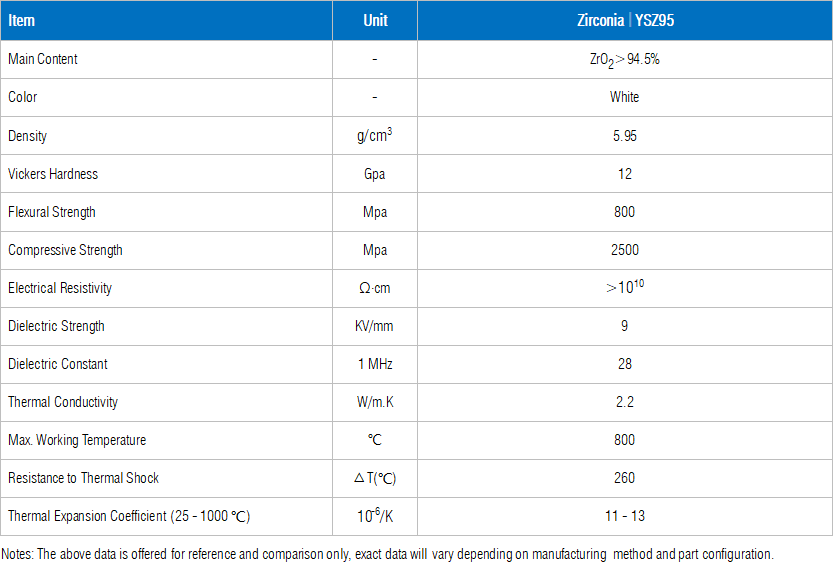

Materials Properties