ZrO2 Zirconia Ceramic Replacement Rectangular Blade

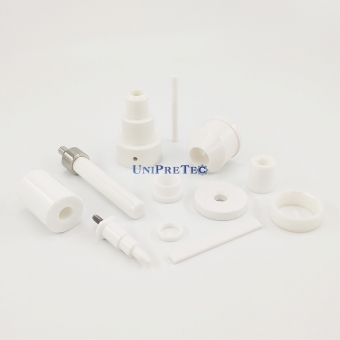

Technical advanced ceramics play important roles in various industries, CUTTING is typically one of them. Although most of advanced ceramics are well known as excellent materials' solutions because of their High Hardness/High Wear & Corrosion Resistance/High Temperature Resistance/Chemical Inertness/Electrical Insulation/Non-magnetic, all of them are brittler when compared to metal. However, Ceramic Blades are still choices for some special applications, where require blades with the aforementioned properties, like the paper and film conversion industries, medical and pharmaceutical applications...

- It can be one hole, two holes, three holes and custom designed.

- deep edged, 2-sided ground edged, ultra sharp and smooth cutting

- never rust, the cutting edge will maintain for long time, no need to be re-sharpened again

- widely deigned for underwater line cutter, hob scraper, film foil slitter.

Considering that Yttria Stabilized Zirconia has the highest fracture toughness among technical ceramics, ZrO2 is chosen as the material of cutting blades. Typical advantages of Ceramic Replacement Blades made of Yttria Stabilized Zirconia are:

Clean Clean

|

High hardness High hardness

|

Non-sparking Non-sparking

|

Long service life Long service life

|

Non-magnetic Non-magnetic

|

Durable sharpness Durable sharpness

|

Chemical inert - never rust Chemical inert - never rust

|

Low coefficient of friction Low coefficient of friction

|

Wear & corrosion resistant Wear & corrosion resistant

|

Electrical insulated (non-conductive) Electrical insulated (non-conductive)

|

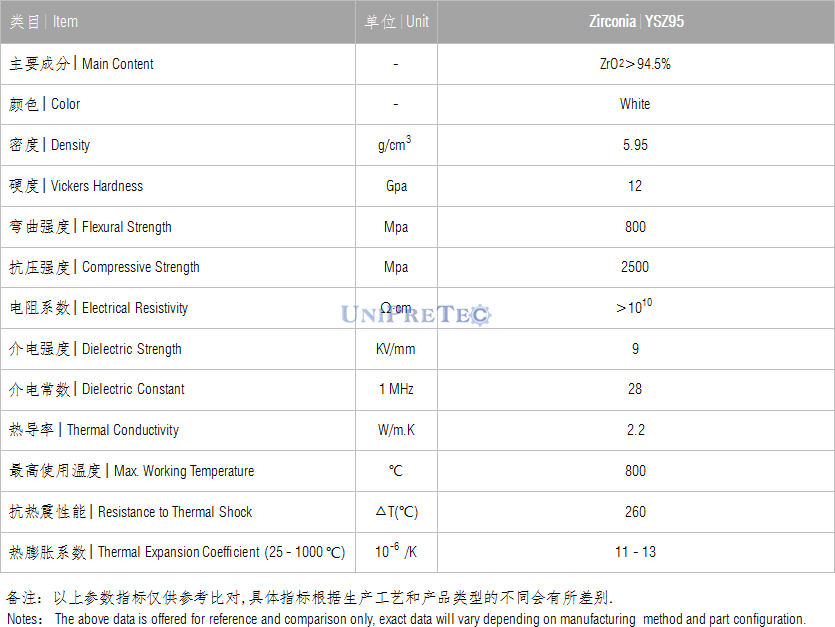

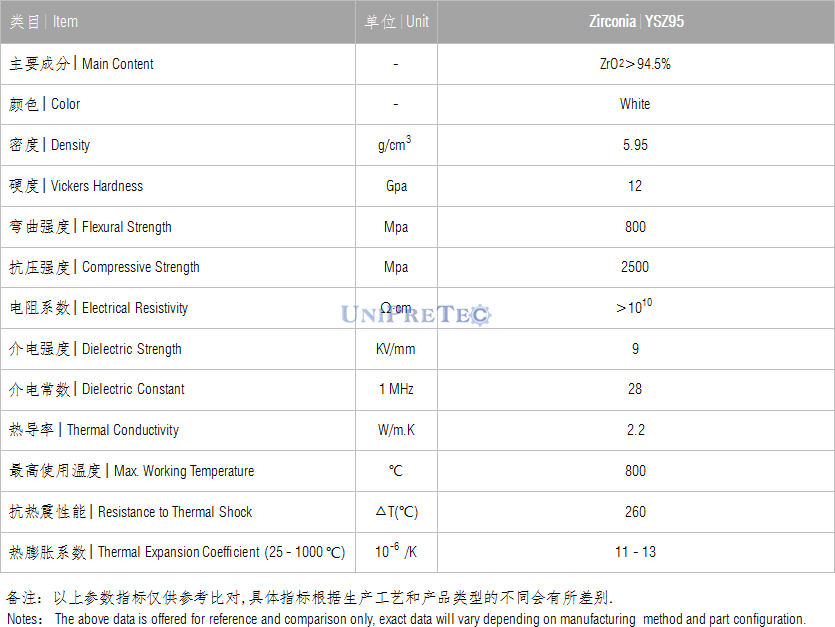

Materials Data Sheet of Zirconia Ceramic Replacement Rectangular Blade

Standard Sizes of Zirconia Ceramic Replacement Rectangular Blade :

42*22*0.2/42*22*0.3/42*22*0.4

Typical Applications of Zirconia Ceramic Replacement Rectangular Blade

Widely deigned for underwater line cutter, hob scraper, film foil slitter(cut optical film, cast film, pearlized film, lithium-ion battery separator film, water soluble film).

Clean

Clean

High hardness

High hardness

Non-sparking

Non-sparking

Long service life

Long service life

Non-magnetic

Non-magnetic

Durable sharpness

Durable sharpness

Chemical inert - never rust

Chemical inert - never rust

Low coefficient of friction

Low coefficient of friction Wear & corrosion resistant

Wear & corrosion resistant

Electrical insulated (non-conductive)

Electrical insulated (non-conductive)