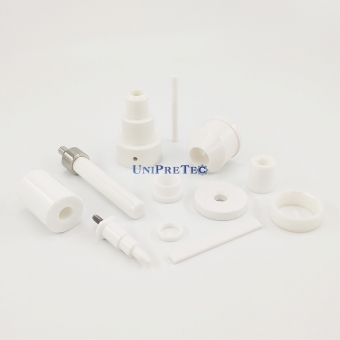

▼ Introduction of Zirconia Ceramic Blades

Due to its property of corrosion resistance, zirconia creamic blade becomes the best choice for capsule cutting. Unlike traditional steel blades, zirconia creamic blade is made of solid zirconia material, so it won’t contaminate capsule. It’s also wear resistant and can serve much longer time than steel blades, that saves time to replace blades and efficiently improves working performance.

Considering that Yttria Stabilized Zirconia has the highest fracture toughness among technical ceramics, ZrO2 Zirconia Ceramic is chosen as the material of cutting blades. Typical advantages of Ceramic Capsule Blades made of Yttria Stabilized Zirconia are:

|

√ Clean

|

√ High Hardness

|

|

√ Non-sparking

|

√ Long Service Life

|

|

√ Non-magnetic

|

√ Durable Sharpness

|

|

√ Chemical Inert - Never Rust

|

√ Low Coefficient of Friction

|

|

√ Wear & Corrosion Resistant

|

√ Electrical Insulated (non-conductive)

|

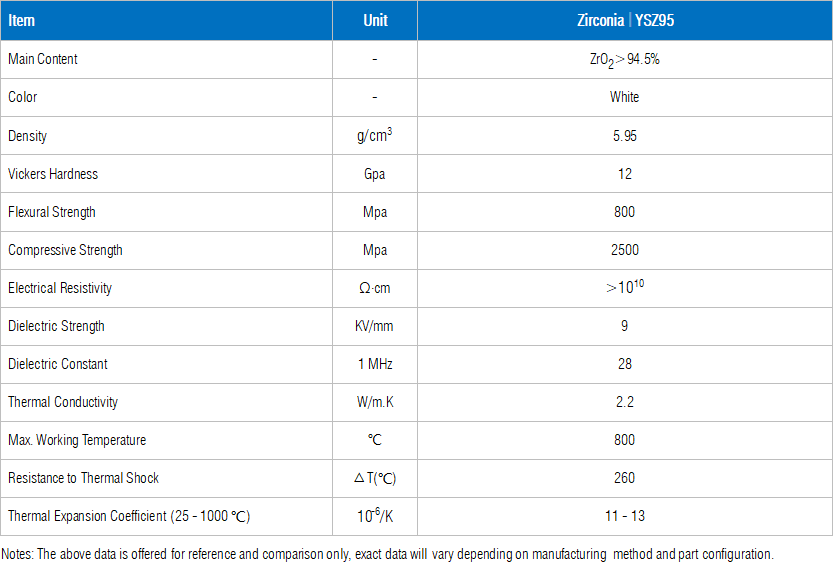

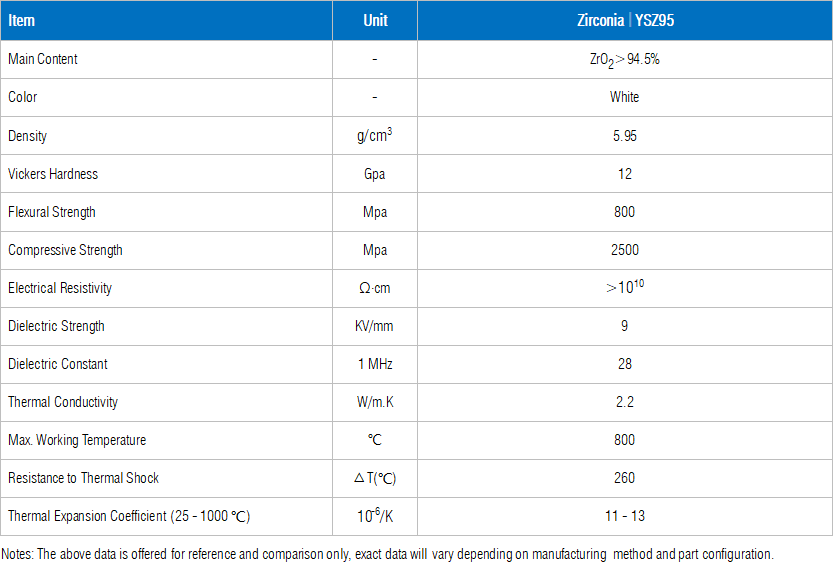

▼ Materials Data Sheet of Ceramic Capsule Blades

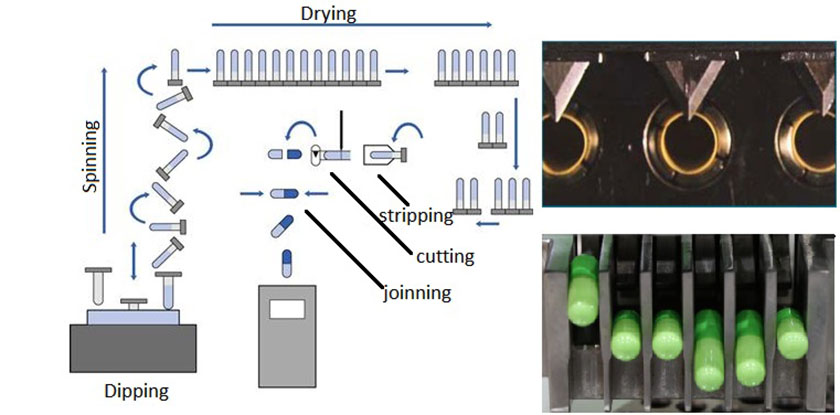

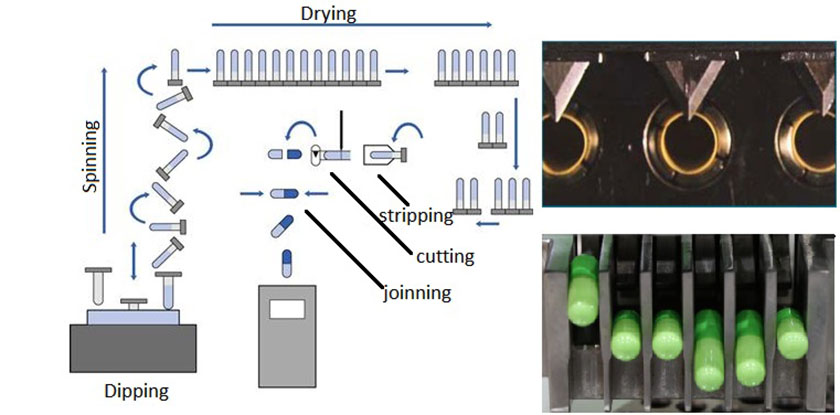

▼ Application Environment of Zirconia Ceramic Capsule Blades