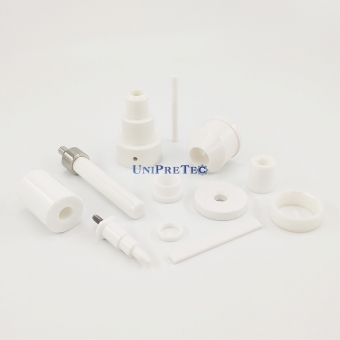

Ceramic Cylinder Liners For Reciprocating Pumps

Due to the ceramic's resistance to pressure, heat, abrasion, and corrosion., UNIPRETEC uses ceramics instead of SUS to make cylinder liners for reciprocating pumps. We are specialized in making ceramic cylinder liners that meet customers' needs in terms of roundness, straightness, surface roughness, etc., and improving work efficiency, product lifetime, and precision.

Ceramic Wear Liners

Ceramic Wear Liners Ceramic Grinding Media

Ceramic Grinding Media

Ceramic Sealing Rings

Ceramic Sealing Rings

Ceramic Electrical Insulator Parts

Ceramic Electrical Insulator Parts

Ceramic Cutting Blades

Ceramic Cutting Blades

Thermal Insulator Components

Thermal Insulator Components

Ceramic Valve Components (valve seats, valve balls...)

Ceramic Valve Components (valve seats, valve balls...)

Ceramic Pump Parts (plungers, piston, sleeve, washer...)

Ceramic Pump Parts (plungers, piston, sleeve, washer...)