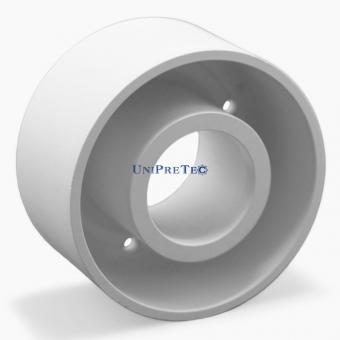

▼ Feuatures of Boron Nitride Nozzles

Excellent Machinability Excellent Machinability

|

Good Chemical Inertness Good Chemical Inertness

|

High Temperature Material High Temperature Material

|

Non-wetted by Molten Metal Non-wetted by Molten Metal

|

Excellent Lubricating Properties Excellent Lubricating Properties

|

Excellent Thermal Shock Resistance Excellent Thermal Shock Resistance

|

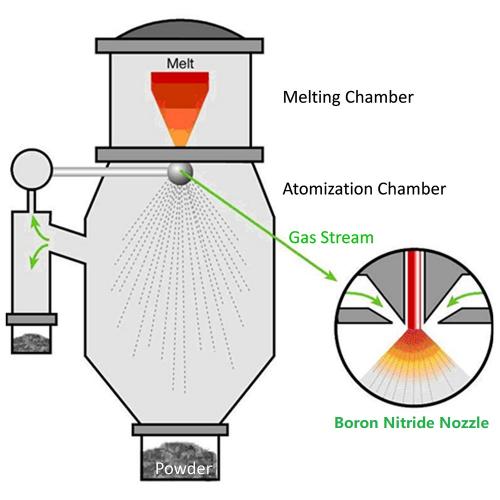

▼ Molten Metal Gas Atomization

Gas atomization technology for molten metal processing is a process that is used to fabricate powders of metals from their melt. In a typical atomizer, the liquid metal is poured down a nozzle into a large chamber while being simultaneously sprayed on by high-pressure jets of gas. This causes the metal droplets to separate and condense into a powder, which collects at the bottom. Gas atomization has established itself as one of the most popular means for powdering metals. In turn, these powders are crucial to 3D printing metallic parts and in the industrial production of certain compounds that cannot be made any other way. UNIPRETEC is the expert of producing suitable nozzles for the gas atomising of metal powders.

▼ Boron Nitride Material for Gas Atomization Nozzles

BN-2300, one of hexagonal boron nitride based composite, has come to be recognized as an exceptional nozzle material as it satisfies all these conditions.

It is a advanced ceramic material with a high melting point, is tough enough to prevent cracks, has high thermal shock resistance, and is easily machinable. In addition, molten metals cannot 'wet' the surface of boron nitride, which means that it is not easily clogged during the atomization process.

Under high vacuum, boron nitride can survive up to 1,750 °C. A gas atmosphere can push this even further to 1,900 °C. This means that boron nitride will remain solid through the melting of most metals. Boron nitride has a very low thermal expansion. Together with the high heat conductivity, this ensures that the material has very high shock resistance. It can easily withstand the rapid gradations in temperature inside the atomizer. It does not break or crack under thermal stresses.

▼ Properties of Boron Nitride Nozzles

|

ITEM

|

UNIT

|

VALUE

|

Main Content

|

-

|

h-BN + Al2O3 + ZrO2

|

Density

|

g/cm3

|

2.25 - 2.35

|

Binder

|

-

|

Boric Oxide

|

Color

|

-

|

Light Grey

|

Compressive Strength (25 °C)

|

Mpa

|

145

|

Flexural Strength (25 °C)

|

Mpa

|

65

|

Thermal Conductivity (25 °C)

|

W/m.K

|

30

|

Thermal Expansion Coefficient (25-1,000 °C)

|

10-6/K

|

2.0

|

Max. Use Temp. (Air Environment)

|

°C

|

1,000

|

Max. Use Temp. (Vacuum Environment)

|

°C

|

1,750

|

Max. Use Temp. (Inert Environment)

|

°C

|

1,900

|

Electrical Resistivity (25 °C)

|

Ω·cm

|

>1013

|

Excellent Machinability

Excellent Machinability Good Chemical Inertness

Good Chemical Inertness High Temperature Material

High Temperature Material Non-wetted by Molten Metal

Non-wetted by Molten Metal Excellent Lubricating Properties

Excellent Lubricating Properties  Excellent Thermal Shock Resistance

Excellent Thermal Shock Resistance