▼ Material Description

The exceptional properties of boron nitride such as high operating temperature and thermal shock resistance are exploited in variety of sintering applications, both in powder form, as a bedding-in powder, and in sintered form using plates and crucibles. Use of Boron Nitride in these applications ensures an even heat transfer to prevent the differential thermal expansions that can lead to the distortion of the finished sintered part.

UNIPRETEC offers different BN grades in the right combination of mechanical strength, high purity and low coefficient. Using of boon nitride sintering crucibles and settes offer multiple runs without warping, easy cleanup between runs, long service life, reduced frequency of replacement, and protection against contact reaction between sintered parts and supporting media.

UNIPRETEC is able to make a broad range of BN crucibles in various sizes and configurations in high volume with a consistent product quality, as our engineers work closely with our customers from design to production to provide crucibles that meet their exacting standards.

▼ Material Feuatures

Good Chemical Inertness Good Chemical Inertness

|

Good Thermal Conductivity Good Thermal Conductivity

|

High Working Temperature High Working Temperature

|

Non-wetted by Molten Metal Non-wetted by Molten Metal

|

Outstanding Lubricating Properties Outstanding Lubricating Properties

|

Excellent Thermal Shock Resistance Excellent Thermal Shock Resistance

|

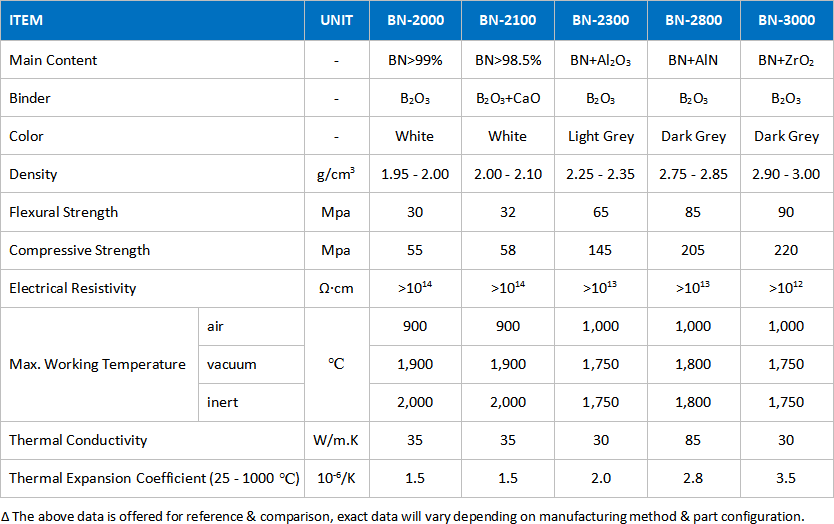

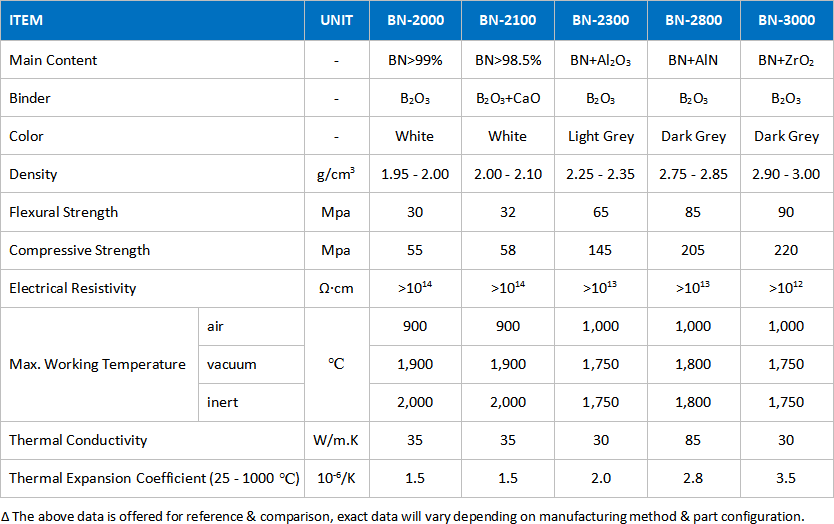

▼ Material Data Sheet

Good Chemical Inertness

Good Chemical Inertness Good Thermal Conductivity

Good Thermal Conductivity High Working Temperature

High Working Temperature Non-wetted by Molten Metal

Non-wetted by Molten Metal Outstanding Lubricating Properties

Outstanding Lubricating Properties  Excellent Thermal Shock Resistance

Excellent Thermal Shock Resistance