Zirconia ceramic ink scraper is made by static pressing and precision grinding. Its hardness is up to 90 HRA. It has incomparable advantages over ordinary steel rings.

Zirconia ceramic has very high wear resistance. Its wear resistance life is more than ten times of that of ordinary steel, its hardness is six times of that of ordinary steel and twice of that of carbon steel. Moreover, the surface smoothness of the product is very high and the friction coefficient is small, so the life of ceramic knife edge cup ring is much longer than that of steel knife edge cup ring.

Zirconia ceramic has small coefficient of thermal expansion and high temperature resistance, which will not cause product damage, deformation, change knife edge precision and affect printing quality because of continuous friction and temperature rise of the ring.

Because the metal ring is easy to release metal ions and react with the ink, which affects the color quality of the ink; at the same time, it is easy to oxidize and form metal filings mixed into the ink, which affects the printing quality. However, the good chemical stability, acid resistance, high temperature resistance, wear resistance, oxidation resistance, magnetic resistance, non-static and good self-lubricating properties of zirconia ceramic ring will not affect the printing quality.

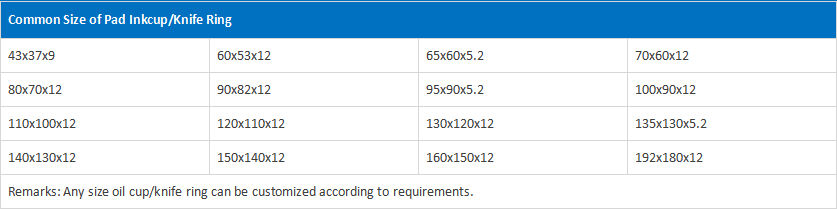

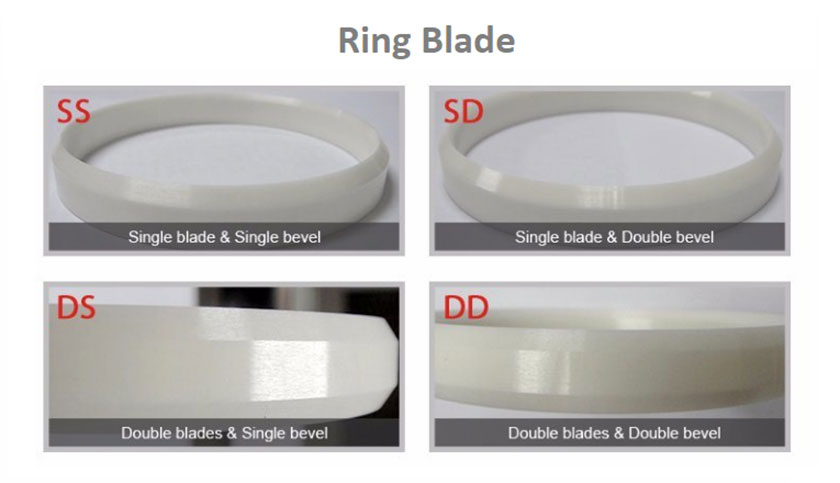

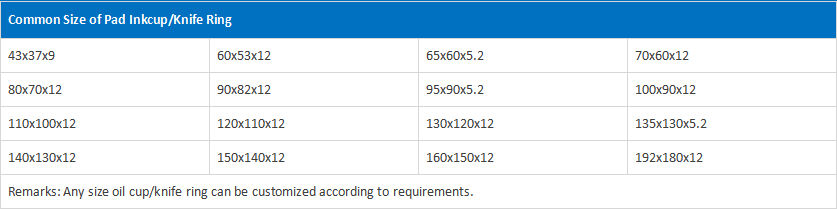

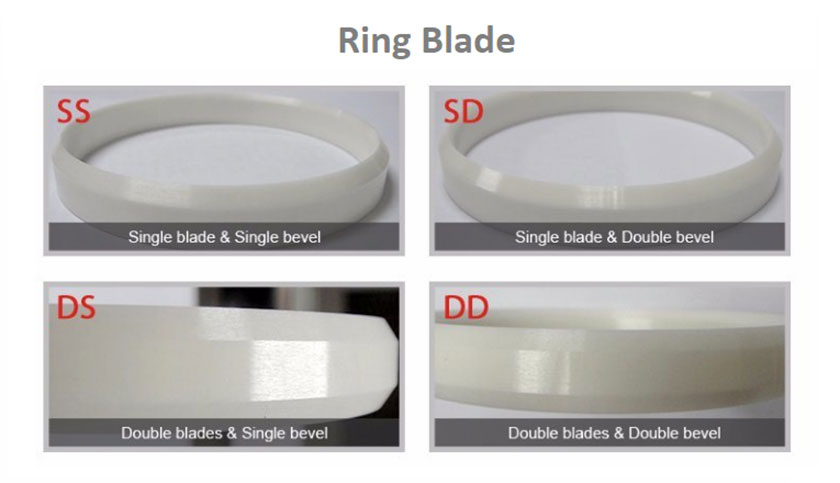

The cutting edge width of the knife ring can be less than 0.1mm, and various types of cutting edges can be processed according to customer requirements; the wall thickness can be less than 3mm; the precision is high, the specifications are complete, and the maximum outer diameter can reach 250mm.