Material Features

- Zirconia beads are made of micron and nano zirconia and yttrium oxide as raw materials;

- Smooth surface, good roundness, pearly luster;

- Has excellent toughness, impact resistance, and is not easy to break during high-speed operation;

- Stable performance, strong acid and alkali resistance;

- Low wear (PPm level), minimal wear on equipmen;

- Very high hardness, not easy to break, which is conducive to the grinding of hard materials;

- Very high density can effectively improve the grinding efficiency.

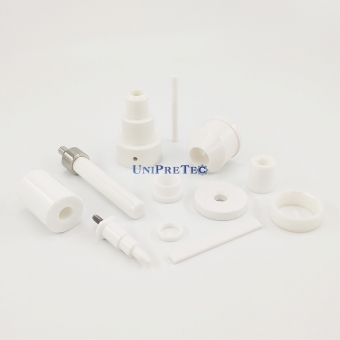

Material Application

Mainly used for ultra-fine grinding and dispersion of materials requiring "zero pollution" and high viscosity and high hardness. Such as: electronic ceramic fragile materials, zirconium oxide, silicon oxide, zirconium silicate, titanium dioxide, medicine, food, pigments, dyes, inks, special chemical industries, papermaking, batteries, and other nano materials.

Regular Size:

Zirconia Ball:

Φ0.1/0.2/0.3/0.4/0.5/0.8/1.0/1.5/2.0/2.5/3.0/4.0/5.0/7.0/8.0/10.0

Φ12.0/15.0/20.0/25.0/30.0/40.0/50.0

Zirconia Cylinder:

Φ5*5 /Φ7*7 /Φ10*10/Φ12.7*12.7/Φ15*15/Φ20*20

Can be customized according to customer requirements.

Material Advantages

High hardness High hardness

|

High fracture toughness High fracture toughness

|

Good chemical inertness Good chemical inertness

|

Long service life (Cost-effective) Long service life (Cost-effective)

|

High wear & corrosion resistance High wear & corrosion resistance

|

High working temperature High working temperature

|

CTE in range of steel CTE in range of steel

|

... ...

|

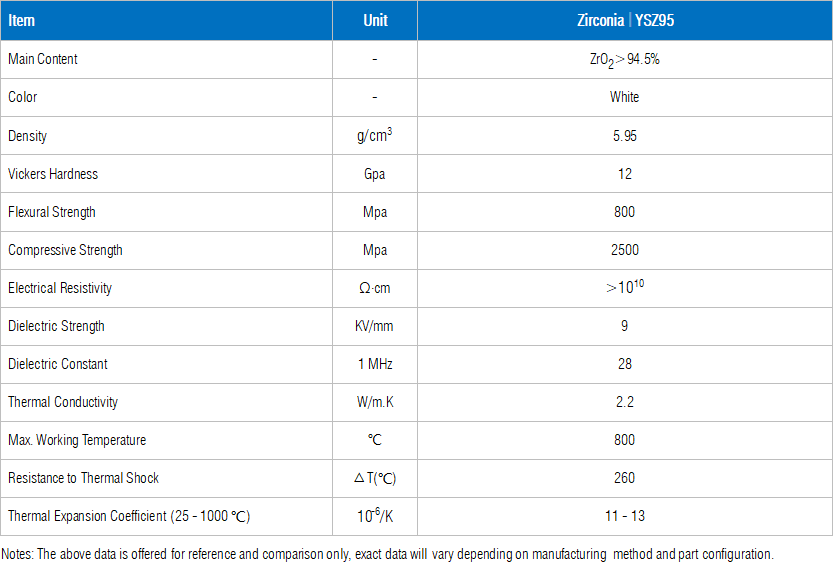

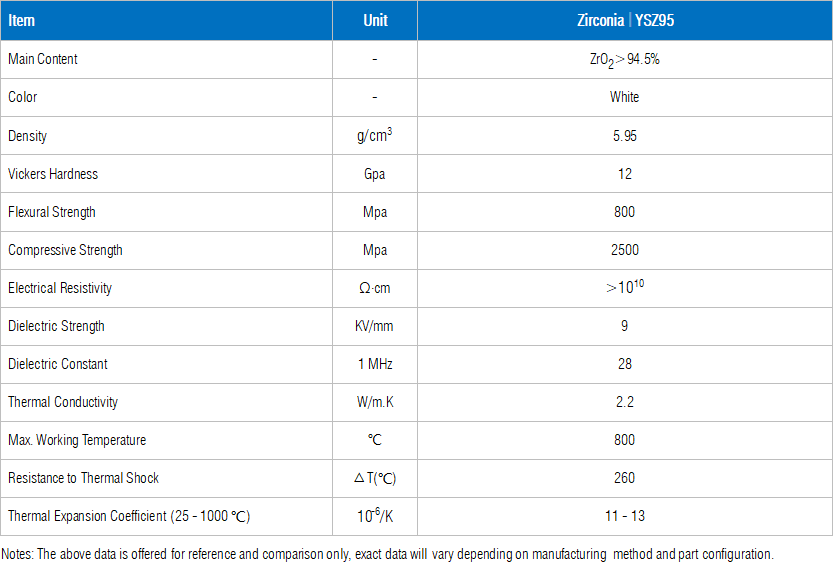

Materials Properties