▼ Description of Alumina Substrates

With the development of electronic equipment, the power is getting higher and higher and the element is getting smaller and smaller, so the requirements for thermal conductivity are getting higher and higher, the previous thermal insulation materials have been more and more unable to meet the demand. In this case, alumina ceramic substrate as a high thermal conductivity and high insulation ceramic material, with 25W/m.k thermal conductivity and 17KV dielectric strength, has become a more and more popular substrate choice of many high-power equipment, compared to the silicon sheet substrate with thermal conductivity only 0.6W/m.k, and the dielectric strength of alumina Al2O3 substrate is also only 2KV.

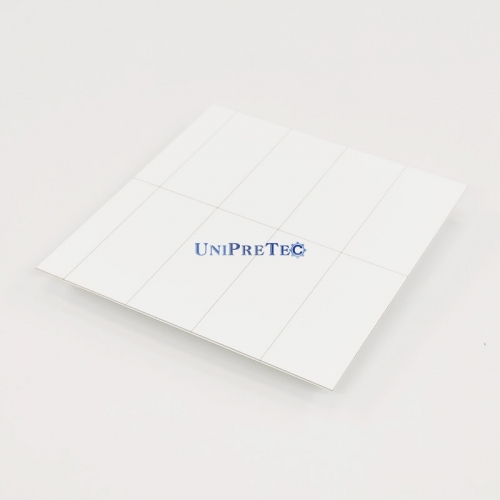

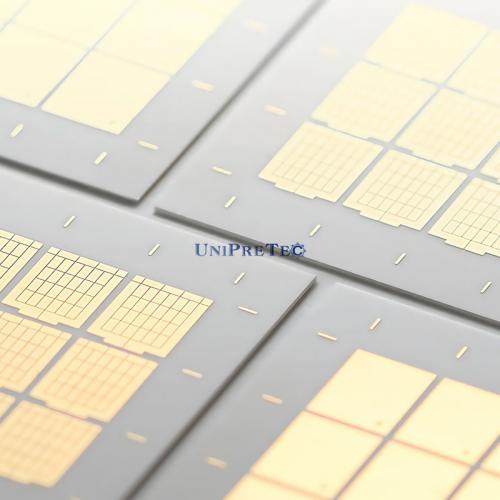

Relying on exceptional performance and very high price/performance ratio, the application of alumina substrate has become wider and wider. As we all know, ceramic is fragile, but our company relies on advanced equipment and many years of production experience, the strength of the production of tape casting alumina substrates on the original basis of the strength greatly improved! Our alumina substrates are made of 96% Al2O3 ceramic, the feaures of our products are as below.

√ Small Dielectric Constant

|

√ Good Thermal Conductivity

|

√ Good Smoothness / Flatness

|

√ Excellent in Electrical Insulation

|

√ Low Thermal Expansion Coefficient

|

√ Good in Thermal Shock Resistance

|

√ Excellent resistance against oil / acid / alkali

|

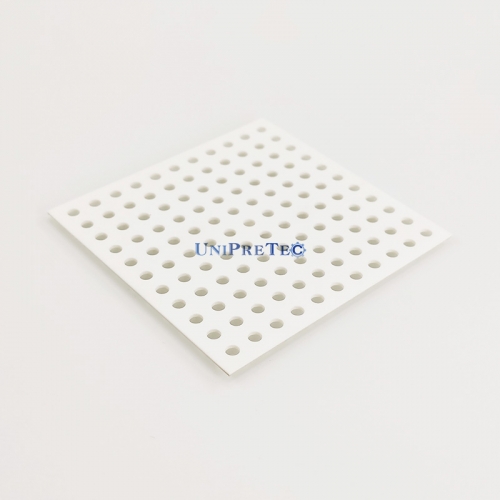

√ Various Specifications in Stock & Fast Delivery

|

▼ Material Properties of Aluminum Oxide Substrates

ITEM

|

UNIT

|

Alumina | A960

|

Main Content

|

-

|

Al2O3 > 96%

|

Density

|

g/cm3

|

> 3.7

|

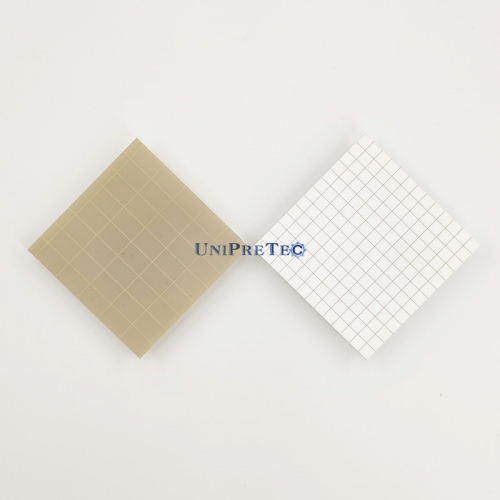

Color

|

-

|

White

|

Water Absorption

|

%

|

0

|

Warpage

|

-

|

< 2‰

|

Standard Surface Roughness (Ra)

|

um

|

0.2 - 0.7

|

Flexural Strength

|

Mpa

|

380

|

Thermal Conductivity (25 °C)

|

W/m.K

|

> 25

|

Thermal Expansion Coefficient (25 - 300 °C)

|

10-6 mm/°C

|

6.5 - 7.5

|

Thermal Expansion Coefficient (300 - 800 °C)

|

10-6 mm/°C

|

6.5 - 8.0

|

Max. Working Temperature

|

°C

|

1,200

|

Dielectric Strength

|

KV/㎜

|

> 17

|

Dielectric Constant

|

1 MHz

|

9 - 10

|

Electrical Resistivity (25 °C)

|

Ω·cm

|

> 1014

|

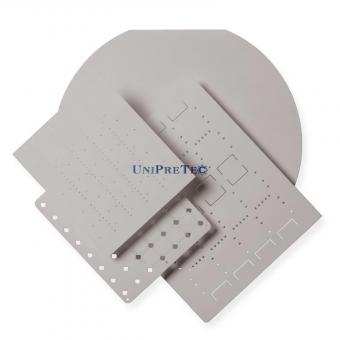

▼ Standard Dimensions and Tolerance

Length and Width

|

Thickness

|

Tolerance (Thickness)

|

110mm x 110mm (4.3" x 4.3")

|

0.25mm (0.010")

|

±0.03mm(<1.0mm)

|

114mm x 114mm (4.5" x 4.5")

|

0.38mm (0.015")

|

±0.05mm(1.0mm - 1.5mm)

|

120mm x 120mm (4.7" x 4.7")

|

0.50mm (0.020")

|

±0.07mm(>1.5mm)

|

127mm x 127mm (5.0" x 5.0")

|

0.63mm (0.250")

|

±0.10mm(>2.0mm)

|

130mm x 140mm (5.1" x 5.5")

|

0.76mm (0.030")

|

|

109mm x 130mm (4.3" x 5.1")

|

1.00mm (0.390")

|

Tolerance (Length and Width)

|

190mm x 140mm (7.5" x 5.5")

|

2.00mm (0.790")

|

+0.25mm/-0.05mm

|

▼ Surface Roughness

All substrates are grinded with surface roughness Ra 0.3-0.6um. We can also do surface polishing, one-side polishing or double-side polishing with surface roughness Ra 0.05-0.10um.

▼ Applications of Al2O3 Ceramic Substrates

● LED Packages

|

● Power Modules

|

● Wafer Bonding

|

● Heat Dissipation Substrate

|

● Substrate for Chip Resistors

|

● HIC Substrate/Plate for Heat Dissipation

|

● FAX Substrates for Thermal Printer Head

|

● ...More

|